Silicon metal manufacturers have turned to Aluminum Lance Pipes as an alternative to oxygen lance pipes to reduce the unintended introduction of iron (Fe) into molten silicon (Si) during the purification process. Aluminum Lance Pipes serve the same purpose but without introducing iron content. This article delves into the structural elements and sizes of Aluminum Lance Pipes, addressing questions about their heat resistance and manufacturing quality.

The Size and Structural Elements of Aluminium Lance Pipes

Source: Daiwa Lance International

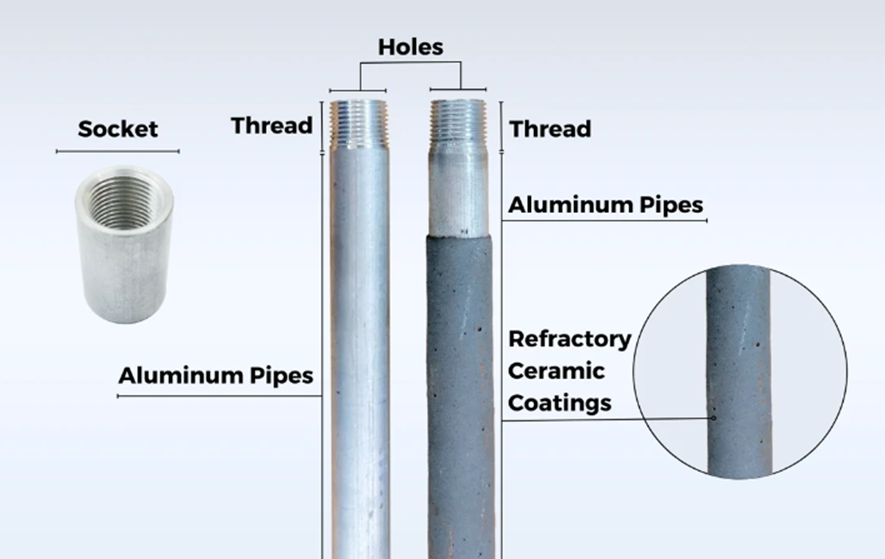

Structural Elements: Aluminum Lance Pipes:

Aluminum Lance Pipes distinguish themselves as a type of oxygen lance pipes, utilizing aluminum as their main component. They possess a cylindrical, hollow pipe design, facilitating the effective and precise conveyance of oxygen in the silicon metal production process. Examining the individual components in detail provides a thorough comprehension of the Aluminum Lance Pipes’ structure.

Structural Elements of Aluminum Lance Pipes

Aluminum Pipes:

Aluminum is the primary material used in the construction of these lance pipes. This strategic choice minimizes the risk of introducing iron content into molten silicon during the oxygen-blowing process.

Refractory Ceramic Coatings:

The surface of Aluminum Lance Pipes is coated with a thick layer of refractory ceramic material. This coating enhances heat resistance, preventing the penetration of heat into the aluminum pipe and maintaining its structural stability. The ceramic coating, with a melting point above 2,000°C, acts as a protective barrier, enabling the lance pipes to withstand extreme temperatures and avoid chemical reactions between molten silicon and aluminum pipes.

Holes:

Aluminum Lance Pipes feature strategically designed holes along their length to facilitate a smooth and uninterrupted flow of oxygen into Submerged EAF (Electric Arc Furnace). The diameter and spacing of these holes are precisely calculated to ensure even distribution of oxygen in molten silicon, allowing for precise temperature control and minimizing iron content.

Thread and Socket:

Thread and socket connections are crucial for joining different lance pipes, ensuring a seamless oxygen flow and minimizing waste during the manufacturing process. Securely fastening one lance pipe to another using thread and socket connections eliminates gaps or openings that could lead to oxygen leakage and reduce lance pipe efficiency.

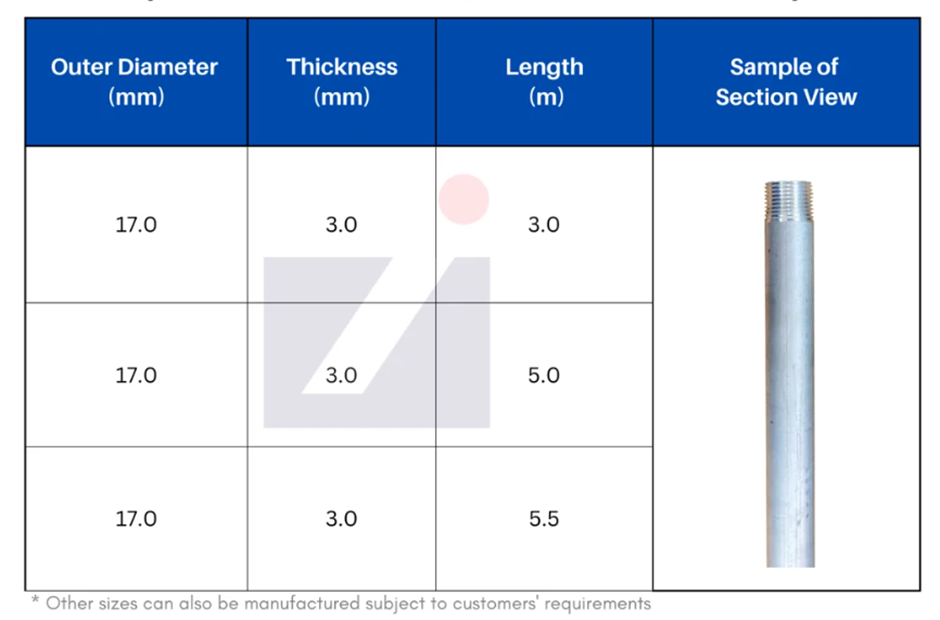

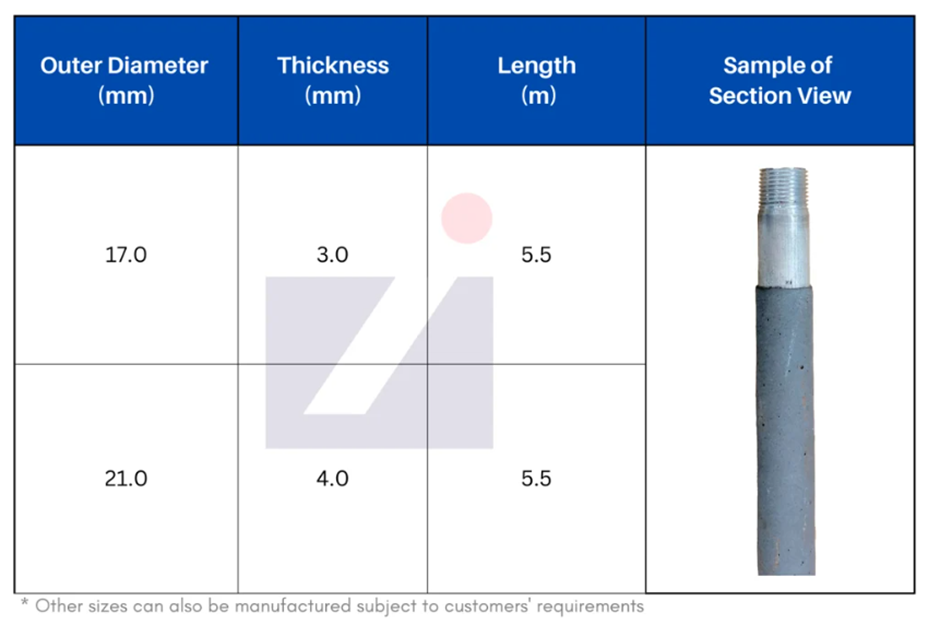

Size of Aluminum Lance Pipes:

We offer a range of sizes for Aluminum Lance Pipes, both with and without ceramic coatings, catering to various production needs in silicon metal manufacturing. Custom sizes are also available to meet unique requirements.

Without Ceramic Coatings:

These are the sizes of Aluminum Lance Pipes without ceramic coatings, designed for specific production needs.

With Ceramic Coatings:

These are the sizes of Aluminum Lance Pipes with ceramic coatings, providing enhanced heat resistance and protection.

Conclusion:

We are committed to delivering high-quality Aluminum Lance Pipes designed for durability and effectiveness in the high-heat environment of molten silicon in Submerged EAF. Custom sizing options are available to accommodate specific requirements. We prioritize product quality and performance to ensure the success of silicon metal production.

For further information regarding Aluminum lance pipes, feel free to reach out to our team at sales@daiwaanayasteel.com.

Daiwa Anaya Steel Private Limited is a part of Anaya Steel, LLC (US parent company). Our company has over 30 years of involvement in steel products. It mostly deals in:

- Specialized steel hardware – punched, pressed, galvanized, powder coated.

- Steel pipes and tubing – specialized, color coated, galvanized and structural.

- Our Lance pipes are produced by Daiwa Lance International in Vietnam.