The metallurgy industry is continuously evolving, with an increasing focus on cost reduction and efficiency enhancement. High-performance oxygen lance pipes play a crucial role in optimizing the metal-making process, and SC Lance stands out as a reliable solution. If traditional black pipes or mild steel pipes seem sufficient for your operations, you may wonder what sets our SC Lance apart. Below are four key advantages that demonstrate why our SC Lance is a superior choice.

Key Advantages of SC Lance for the Metallurgy Industry

Source: Daiwa Lance International

1.Superior Raw Material Selection

The foundation of a high-quality oxygen lance pipe lies in the selection of premium raw materials. Our SC Lance is manufactured using high-quality steel coils sourced from one of Japan’s leading steel producers. These steel coils are known for their consistent structure, exceptional purity, and superior durability, ensuring optimal performance even in extreme conditions. The precise selection of raw materials contributes to the pipe’s resistance to high temperatures, enhancing its lifespan and efficiency in metal processing applications.

2. Advanced Surface Treatment for Enhanced Safety

Surface treatment is a critical step in ensuring both product quality and user safety. SC Lance undergoes meticulous cleaning processes to remove oil, grease, and other contaminants that could lead to hazardous conditions, such as fire accidents caused by furnace flames encountering residual oil. Additionally, deburring techniques are applied to eliminate sharp edges and metal chips, reducing the risk of injuries during handling. For long-term preservation, optional rust removal services are also available, further enhancing the pipe’s durability and reliability.

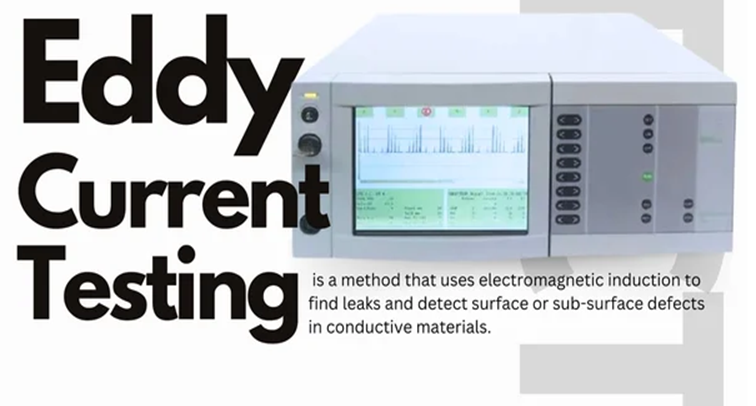

3. Airtight Welding Seams for Leak Prevention

Achieving flawless welding seams is essential for ensuring the efficiency and safety of oxygen-blowing operations. SC Lance undergoes a rigorous two-step inspection process to guarantee airtight welding seams:

• Eddy Current Testing (ECT): This non-destructive testing method is employed to scan the entire pipe for any internal defects or inconsistencies.

• Flattening Test: A small section of the pipe is cut and subjected to high pressure to assess its structural integrity and detect potential cracks.

These stringent quality control measures ensure that SC Lance provides leak-free performance, preventing gas loss and maintaining process efficiency.

4. Compliance with International Quality Standards

Adhering to globally recognized standards is a key aspect of manufacturing high-performance oxygen lance pipes. SC Lance is produced in compliance with:

• JIS G3452: This standard defines the chemical composition, mechanical properties, dimensions, and thickness requirements for steel pipes, ensuring structural reliability.

• ISO 9001: A quality management standard that guarantees consistent manufacturing processes and superior product performance.

• ISO 14001: An environmental management standard that ensures sustainable production practices while minimizing environmental impact.

The integration of these standards underscores a commitment to both product excellence and environmental responsibility.

Conclusion

SC Lance offers a combination of high-quality raw materials, meticulously treated surfaces, airtight welding seams, and adherence to international standards—making it a top-tier choice for oxygen lance applications in the metallurgy industry. For further details on how SC Lance can enhance your operations, feel free to reach out and explore tailored solutions for your specific requirements. For more information, please contact our sales team at sales@daiwaanayasteel.com

Daiwa Anaya Steel Private Limited is a part of Anaya Steel, LLC (US parent company). Our company has over 30 years of involvement in steel products. It mostly deals in:

Daiwa Anaya Steel Private Limited is a part of Anaya Steel, LLC (US parent company). Our company has over 30 years of involvement in steel products. It mostly deals in: