Aluminium casting is a critical process across industries such as automotive, aerospace, and construction. However, one of the biggest challenges in aluminium melting is maintaining metal purity. Impurities like oxides and dissolved hydrogen gas can lead to porosity, inclusions, and reduced mechanical strength — ultimately compromising the quality of the final product.

The key to overcoming these issues lies in effective flux injection. Flux not only removes impurities and degasses the melt but also ensures cleaner and stronger castings.

Effective Flux Injection Techniques for Removing Impurities in Aluminum Melting

Source: Daiwa Lance International

What Is Flux Aluminium Melting?

Flux is a carefully formulated mixture of chloride and fluoride salts used in aluminium foundries to refine molten metal. When introduced properly, flux performs several crucial functions during the melting process.

Key Benefits of Using Flux:

Prevents Oxidation: Flux forms a protective layer over molten aluminium, minimizing contact with oxygen.

Removes Hydrogen: It absorbs dissolved hydrogen gas, preventing porosity in the casting.

Eliminates Inclusions: Flux captures oxides and slag particles suspended in the melt.

Cleans Furnace Walls: It prevents oxide buildup on furnace linings, extending furnace life.

Improves Grain Structure: Promotes uniform and refined grain formation for better strength.

Enhances Alloy Quality: Helps modify silicon distribution in aluminium-silicon alloys for improved properties.

Simply adding flux is not enough — the method of introducing it into the melt determines how effectively impurities are removed.

Methods of Introducing Flux into Molten Aluminium

There are two common ways to add flux to molten aluminium — manual application and injection methods. Each has its advantages and limitations.

1. Manual Flux Application (Traditional Method)

In the manual approach, flux powder is sprinkled over the surface of the molten aluminium. The operator then stirs it using a rod or a perforated bell tool to help the flux mix into the melt.

This method is simple and inexpensive, making it suitable for small-scale foundries. However, it often results in uneven flux distribution and higher flux consumption. Moreover, the operator is exposed to fumes and heat, which raises safety concerns.

2. Flux Injection (Advanced Method)

Flux injection involves blowing flux powder into the molten aluminium with the help of an inert gas such as Argon or Nitrogen. This method ensures that the flux reaches deeper regions of the melt for better purification.

There are two common injection techniques:

a. Basic Lance Injection

In this method, a lance pipe is immersed into the melt, allowing a controlled mix of gas and flux to flow through. The flux disperses more evenly, improving impurity removal and reducing material wastage.

However, the effectiveness depends largely on proper injection technique and the quality of the lance pipe, which must withstand intense heat and corrosion.

b. Rotary Degasser Injection

Here, a rotating impeller disperses flux uniformly throughout the molten aluminium. This technique provides superior degassing and impurity removal efficiency, making it ideal for large-scale industrial applications. The only drawback is its higher equipment and maintenance cost compared to lance injection systems.

How to Inject Flux Effectively Using a Lance

Flux injection through a lance is considered one of the most cost-effective and efficient solutions for improving melt quality without heavy capital investment. To achieve the best results, two things matter most — the injection technique and the selection of a suitable lance.

1.The Right Flux Injection Technique

A few operational parameters play a key role in ensuring proper flux dispersion:

Immersion Depth: The lance should be immersed deep enough to allow flux to reach all parts of the melt, but not so deep that it causes splashing.

Gas Flow Rate: Maintain a steady and moderate gas flow. Excessive pressure causes turbulence, while too little reduces flux spread.

Injection Time: Allow adequate reaction time based on melt volume to ensure complete purification.

2. Choosing the Right Injection Lance

A lance pipe must endure extreme furnace conditions without deforming or cracking. The right material can dramatically improve performance and lifespan.

Essential properties:

High-Temperature Strength: Should withstand temperatures above 700°C without structural damage.

Oxidation Resistance: Coatings or special surface treatments prevent corrosion and degradation.

Mechanical Durability: Should resist thermal shock and abrasion during repeated immersion.

Even Gas Flow: Uniform nozzle design ensures consistent gas distribution and minimizes flux waste.

Recommended Refractory Products for Flux Injection

The performance of your flux injection process depends heavily on the type of lance you use. Here are two commonly used options in aluminium melting operations.

Option 1: Mild Steel Pipe

Mild steel (or black pipe) lances are widely used because they’re cost-effective and readily available. They are suitable for small foundries or intermittent melting processes.

However, in high-temperature environments (above 700°C), the steel surface tends to oxidize and weaken over time. With regular use, the pipe’s wall thickness reduces significantly within a few months, increasing the risk of cracking during thermal cycling.

This makes mild steel lances a good short-term solution but not ideal for continuous operations, where frequent replacements lead to higher long-term costs and downtime.

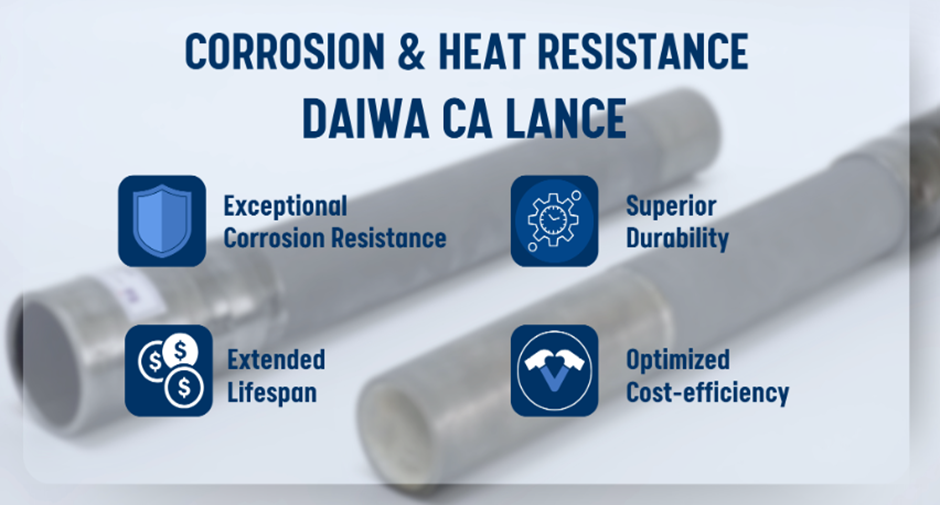

Option 2: Calorized Ceramic-Coated Lance Pipe

For more demanding and continuous melting operations, calorized ceramic-coated lances offer a long-lasting and reliable alternative.

These pipes undergo a metallurgical diffusion treatment combined with a ceramic coating process. The inner layer forms a bonded alumina (Al₂O₃) diffusion barrier, while the outer ceramic layer provides additional protection against heat and corrosion.

Benefits include:

- Extended lifespan — typically 3 to 7 times longer than mild steel pipes.

- Excellent resistance to oxidation, corrosion, and thermal shock.

- Reduced maintenance and fewer replacements.

- Consistent performance in high-temperature environments.

Although they require a slightly higher initial investment, their durability and performance make them more economical and efficient in the long run.

Conclusion

Effective flux injection is not just about using the right flux — it’s about combining the correct technique with a durable and well-designed lance. When both elements are optimized, aluminium melts become significantly cleaner, more consistent, and better suited for high-performance applications.

Cleaner metal means fewer defects, stronger castings, and greater efficiency — all key factors in maintaining quality and competitiveness in modern aluminium foundries. For more information, please contact our sales team at sales@daiwaanayasteel.com.

Daiwa Anaya Steel Private Limited is a part of Anaya Steel, LLC (US parent company). Our company has over 30 years of involvement in steel products. It mostly deals in:

- Specialized steel hardware – punched, pressed, galvanized, powder-coated.

- Steel pipes and tubing – specialized, color coated, galvanized, and structural.

- Our products are produced by Daiwa Lance International in Vietnam.