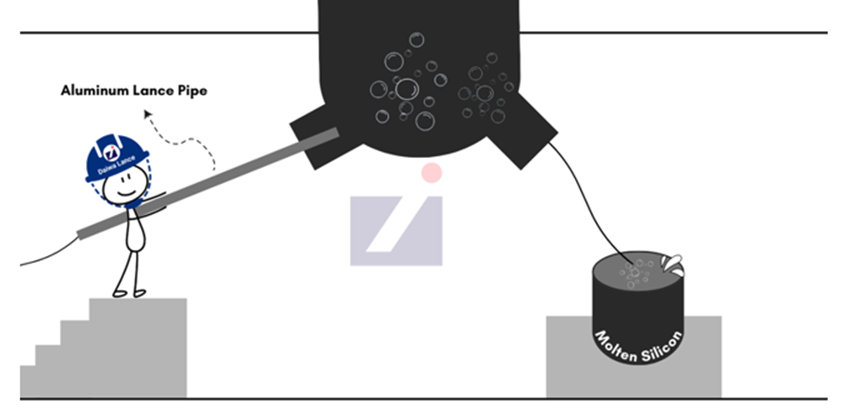

The production of silicon metal involves several critical steps, with the refining process being a pivotal stage where high temperatures and nonferrous materials are essential for blowing gases. Aluminum Lance Pipes, whether equipped with a refractory ceramic coating or not, are well-known for their exceptional thermal conductivity and resistance to corrosion. This makes them an optimal choice in the production of silicon metal, ensuring the creation of high-grade, pure silicon. In this blog post, we will delve into how Aluminum Lance Pipes contributed to this remarkable outcome.

Aluminum Lance Pipes in Silicon Metal Production

Source: Daiwa Lance International

Phases in Silicon Metal Production

Understanding the unique qualities of Aluminum Lance Pipes begins with a walkthrough of the crucial stages involved in producing silicon metal.

- Raw Material Selection

The initial phase of silicon metal production involves the extraction of raw materials, primarily quartz, which is then crushed and heated to yield silicon dioxide (SiO2). This SiO2 is subsequently mixed with carbon and subjected to high-temperature treatment in a submerged electric arc furnace (EAF), resulting in the production of silicon metal. - Reduction

After obtaining silicon metal, it undergoes a refining process to eliminate impurities and enhance its purity. This refining process relies on high temperatures and blowing gases to achieve the desired outcome, where Aluminum Lance Pipes play a pivotal role. - Purification

Following the reduction phase, the silicon obtained may still contain slight impurities. Various purification techniques, such as zone refining, chemical vapor deposition (CVD), and the Siemens process, are employed to eliminate these impurities and improve the overall purity of the silicon metal. - Crystallization

The purified silicon is melted and carefully crystallized to form large, uniform crystals, contributing to the excellent electrical properties of high-grade silicon. - Doping

Doping refers to the deliberate introduction of impurities into a semiconductor crystal to precisely modify its conductivity. Controlled amounts of dopants are introduced to modify silicon’s electrical properties, a crucial step in producing semiconductors used in electronics.

Aluminum Lance Pipe

Aluminum Lance Pipe is a specialized type of oxygen lance pipe used in the production of silicon metal, a key raw material in solar panel and semiconductor manufacturing. It is employed to introduce oxygen into the submerged electric arc furnace (Submerged EAF), regulating temperature flow and reducing iron content. This precise control ensures the production of specific silicon quantities, enabling the creation of both high-grade and low-grade silicon metal.

Use of Aluminum Lance Pipe for Silicon Metal Production in Submerged

Usage of Aluminum Lance Pipe in the Production of Silicon Metal

Aluminum Lance Pipe is the preferred choice when producing high-purity silicon metal, where oxygen lance pipes containing significant iron content are ineffective. During the silicon metal production process, heat-resistant materials are used to inject oxygen into the Submerged EAF. The presence of iron content in oxygen lance pipes can lead to unwanted reactions with silicon oxide, impeding the purification process. Substituting them with aluminum lance pipes effectively mitigates this issue, allowing for precise control of oxygen quantity and temperature, thereby facilitating the production of high-grade silicon metal.

Types of Aluminum Lance Pipe

We offer two options for Aluminum Lance Pipe products to meet specific usage requirements. These include Aluminum Lance Pipes with ceramic coatings and those without. The ceramic-coated versions excel in withstanding the high temperatures within the Submerged EAF, thanks to the combination of aluminum’s low melting point and the added heat resistance of the ceramic layers. This innovation reduces operational burden by ensuring a heat-resistant thickness without unnecessary weight.

Image of Aluminum Lance Pipe without Ceramic Coating

Image of Aluminum Lance Pipe with Ceramic Coating

Conclusion

In conclusion, the use of Aluminum Lance Pipe in silicon metal production is a critical step, ensuring the production of high-grade pure silicon. By introducing oxygen into the Submerged EAF, Aluminum Lance Pipe regulates temperature flow and reduces iron content, enabling the precise control of silicon quantities.

For further information regarding Aluminum lance pipes, feel free to reach out to our team at sales@daiwaanayasteel.com.

Daiwa Anaya Steel Private Limited is a part of Anaya Steel, LLC (US parent company). Our company has over 30 years of involvement in steel products. It mostly deals in:

- Specialized steel hardware – punched, pressed, galvanized, powder coated.

- Steel pipes and tubing – specialized, color coated, galvanized and structural.

- Our Lance pipes are produced by Daiwa Lance International in Vietnam.