Lance pipes are the additional alternatives for using steel pipes to enhance effectiveness depending on the uses and application for lancing activities. It becomes difficult for the customers to find the best lancing option that is suitable for a particular scenario so as to increase overall efficiency. This is the reason we try to explain our lancing products to our esteemed customers so that it helps them to find the appropriate product that will fit as per the requirement.

Therefore, today we shall be explaining about the CC Lances and its applications in various fields because of its corrosion resistance and moderate heat level characteristics.

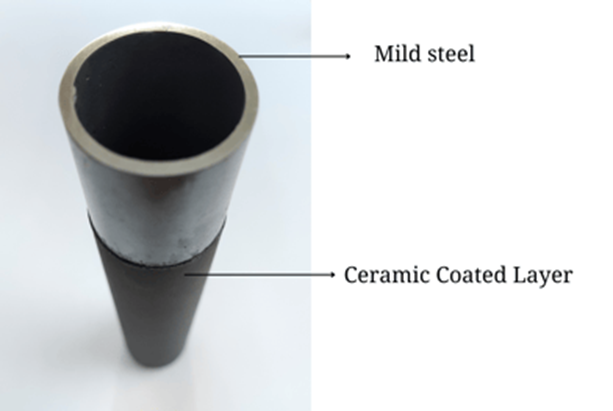

Ceramic Coated Lance Pipe: Structure and Applications

Source: Daiwa Lance International

Ceramic Coated (CC) Lance Pipes are a special type of lances that are manufactured by applying a distinct refractory coating both inside and outside of normal mild steel pipe. The refractory coating is applied depending upon the normal bore of the pipe. This enhances the resistance of the CC Lance Pipes better to the attack the liquid metal and slag.

It is generally used in Electric Arc Furnace (EAF) for blowing oxygen and other gas. More than 1-time coating layers can be provided, depending on each customer’s requirement. If we compared Calorized Lance pipe to Ceramic Coated Lance pipe, then the latter is easier to burn during usage.

Structure of the CC Lances

The image below shows the structure of the CC Lance Pipe.

Basic structure – CC lance Pipe

Applications of the CC Lance Pipe

CC Lance pipes are oxygen lance products which are in general used for carbon and oxygen injection for steel making process in an electric arc furnace. In the case of CA Lances, oxygen and carbon are blown through the lance pipes which are inserted into the melted iron. Then after pouring out the liquid steel, the workers use the CC Lance pipes to clean stuck metal inside the converter.

Slag on Steel Mill Floor

Operator Removing Slag

Our CC lance pipes are also applicable for silicon metal production through smelting, which is a primary step to producing solar panels. Silicon metal is the primary material for producing solar panels.

Silicon Metal

Differences:

MS Lance Pipe, CC Lance Pipe and CA Lance Pipe

| Type | MS pipe | CC Lance pipe | CA Lance pipe |

| Applications | Structure Automobile Construction purposes Steel Manufacturing | Steel Manufacturing Silicon Metal smelting | Steel Manufacturing Aluminum & Copper smelting |

| Hardness / Toughness | Normal | Good | Excellent |

| Heat Resistance Performance (Internal Testing Result – under Oxygen Acetylene Torch Flame at 3000oC) | 20 seconds | 47 seconds | 151 seconds |

Half cut inner view of the SC, CC, CA Lance Pipes

Conclusion

We hope the above information is useful for the basic understanding of the CC Lances. We always recommend CC Lance Pipes for applications in tap hole cleaning or nozzles opening in ladles, construction, other applications, powder injections etc. since the ceramic coating on the mild steel pipe improves the resistance of the pipe against the attack from slag or liquid metal. Also, it is cost effective.

To know more about our CC Lance Pipes, kindly write us at sales@daiwaanayasteel.com.

We are always at your disposal.

Daiwa Anaya Steel Private Limited is a part of Anaya Steel, LLC (US parent company). Our company has over 30 years of involvement in steel products. It mostly deals in:

- Specialized steel hardware – punched, pressed, galvanized, powder coated.

- Steel pipes and tubing – specialized, color coated, galvanized and structural.

- Our Lance pipes are produced by Daiwa Lance International in Vietnam.