In this concise guide, we will be presenting a comprehensive overview of Calorized Lance Pipes, covering essential aspects such as its definition, manufacturing technology, structure, applications, types, sizes, and connection methods. Our goal is to provide all the necessary information, making it effortless to understand this specialized product.

Comprehensive Overview of Calorized Lance Pipes

Source: Daiwa Lance International

What is Calorized Lance Pipe?

Calorized Lance Pipe, also known as an oxygen blowing lance, plays a crucial role in the steelmaking process by injecting oxygen, carbon, or other additives. To achieve high heat and oxidation resistance, these pipes undergo a calorizing process.

Technology for Making Calorized Lance Pipes

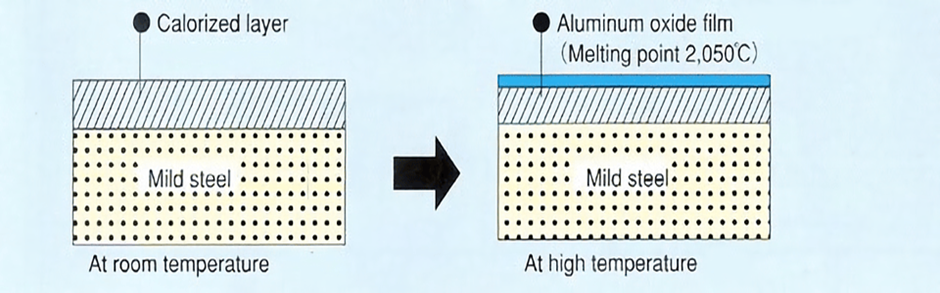

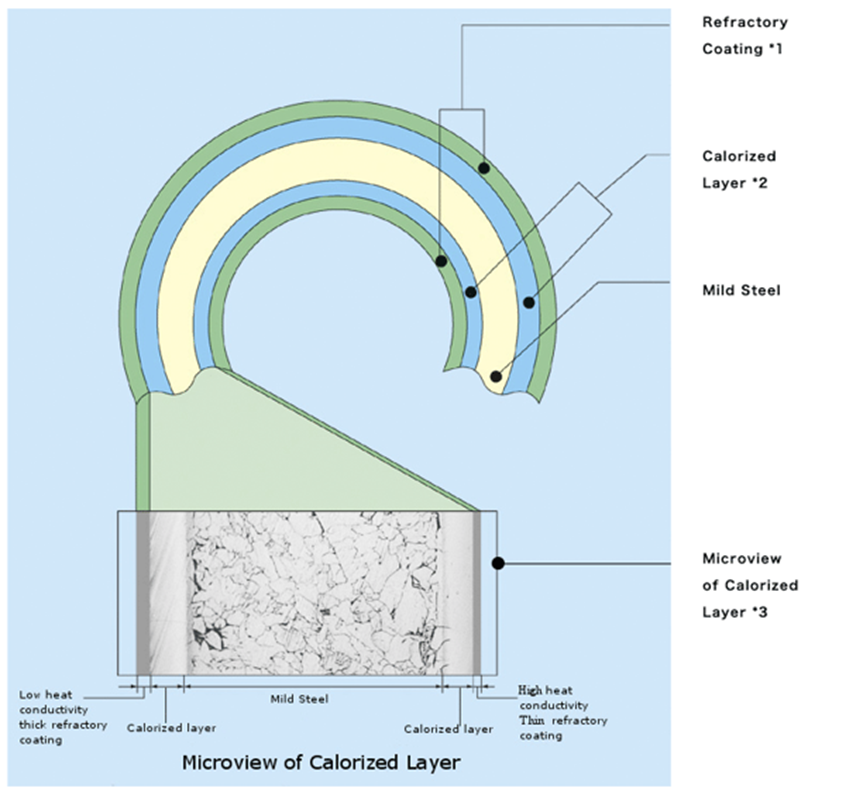

The manufacturing technology behind Calorized Lance Pipes is known as “Calorizing” or aluminum diffusion. This surface modification process diffuses aluminum into steel pipes, both internally and externally, protecting the base metal from severe oxidation and corrosion in high-temperature environments.

How is Calorized Lance Pipe Manufactured?

Using diffusion technology, mild steels are heated to 1,000°C, allowing aluminum to penetrate the material and create a durable aluminum-iron alloy (calorized layer) on both inner and outer surfaces. The product then undergoes a ceramic coating process to enhance heat and oxidation resistance.

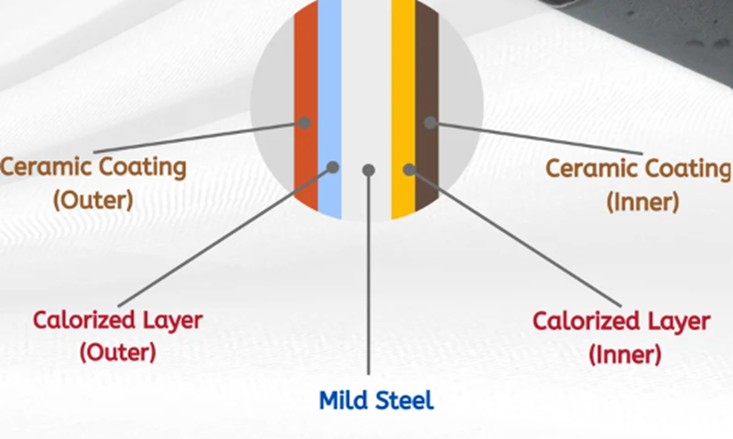

Structure of Calorized Lance Pipes

Calorized Lance Pipes consist of:

Ceramic Coating (Inner Surface)

Calorized Layer (Inner Surface)

Mild Steel Core

Calorized Layer (Outer Surface)

Ceramic Coating (Outer Surface)

Applications of Calorized Lance Pipes

These pipes find extensive applications in the steel industry, serving purposes such as injecting/blowing gases in electric arc furnaces, increasing oxygen supply in incinerators, cleaning slags in oxygen converters, opening tapholes, reducing carbon content in induction furnaces, and protecting thermocouples in measuring molten metal temperatures.

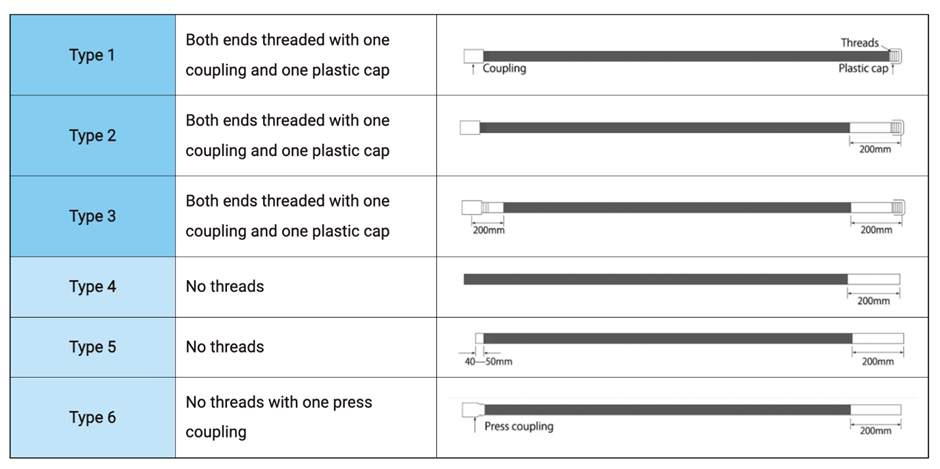

Types and Sizes of Calorized Lance Pipes

There are six types of Calorized Lance Pipes, each catering to specific needs. Common sizes include various diameters and lengths, with the option for custom lengths and OD based on customer requirements.

Connection Methods for Calorized Lance Pipes

To optimize costs and materials, three connection methods are available: thread & socket, welding, and threadless using the Press Machine.

Conclusion:

With this comprehensive guide, now we have a thorough understanding of Calorized Lance Pipes, empowering to make informed decisions and confidently navigate the realm of this specialized product.

For further information regarding CA lance pipes, feel free to reach out to our team at sales@daiwaanayasteel.com.

Daiwa Anaya Steel Private Limited is a part of Anaya Steel, LLC (US parent company). Our company has over 30 years of involvement in steel products. It mostly deals in:

- Specialized steel hardware – punched, pressed, galvanized, powder coated.

- Steel pipes and tubing – specialized, color coated, galvanized and structural.

- Our Lance pipes are produced by Daiwa Lance International in Vietnam.