There are several needs required to enhance the performance of inserting/ blowing inert gas to prevent oxidization with useful tools during smelting of Aluminum. Also, there is a requirement, to test out the temperature of molten aluminum to control the flow of the metal effectively. In due course, the production process also involves tools with good performance to clean up spattered aluminum metal on the furnace walls and floor. It is ideal that aluminum producers can understand well what nature of pipe can be employed for each of their production steps to lower their cost and enhance efficiency.

In this blog, we shall explain the production process of aluminum refining and also introduce our lance pipes appropriate for each step of production.

Improving Work Efficiency in Aluminium Melting Furnaces

Aluminum Production Process

There are several processes in the Aluminum production, and we would summarize the main processes as below:

Step 1: Aluminum Refining

To get one ton of alumina, two to three tons of bauxite are required. During the absorption process, boiling caustic soda is utilized to the bauxite to dissolve the minerals that include aluminum. Over sedimentation, the bauxite solids separate from the pregnant liquid. Crystallization in the precipitation stage eliminates alumina crystals from the liquid. Calcination is a unique technique to get rid of any leftover water.

Step 2: Aluminum Smelting

The Hall-Héroult technique is used to smelt alumina into aluminium. Production of one tonne of aluminium involves around two tonnes of alumina. Alumina is dissolved in an electrolytic bath of molten salt known as cryolite at temperatures of around 960°C. This mixture is then injected with an electrical current of 400 KA or greater amperage. Liquid aluminium is then deposited in the bottom of the pot and therefore the current ruptures the connection between the aluminium and oxygen atoms in alumina.

Step 3: Casting

Then, aluminium is forwarded to the casting facility, where it is used to create supplies in a range of different ways. Various products have alloys added before the solidification step in accordance with customer specifications. In re-melt casting, liquid aluminium is injected into molds at a temperature of more than 700°C and the molds are cooled and solidified before the metal is packaged and sent to the client.

Cast aluminium slabs are heated and put through a series of rollers in sheet ingot casting until the desired plate of thickness is attained or the metal is thin enough for cold rolling, or the slabs are cut into plates. In case of billet casting, hot cast aluminium billets are either forged into numerous products, including automobile components and wheels, or extruded through a steel die to produce profiles.

Inserting Inert Gas to Aluminum Smelter

In aluminum smelters, the main challenge is to search for tools that are good enough to prevent oxidation. By blowing inert gas into the melting furnace, it is easy to have corrosion and diminishes the life of steel tubes. Having long-lasting life would be helpful and reduce costs by less quantity.

Worker injecting Inert gas into the Aluminum Smelter

In this context, we would like to throw light on our product line that will be useful in this process.

Calorized (CA)

Lance Pipe is used for carbon and oxygen injection for steel making process mainly with electric arc furnace and also, this pipe suggested to be used in Aluminum Smelter for blowing inert gas, due to its extraordinary quality that can prevent corrosion.

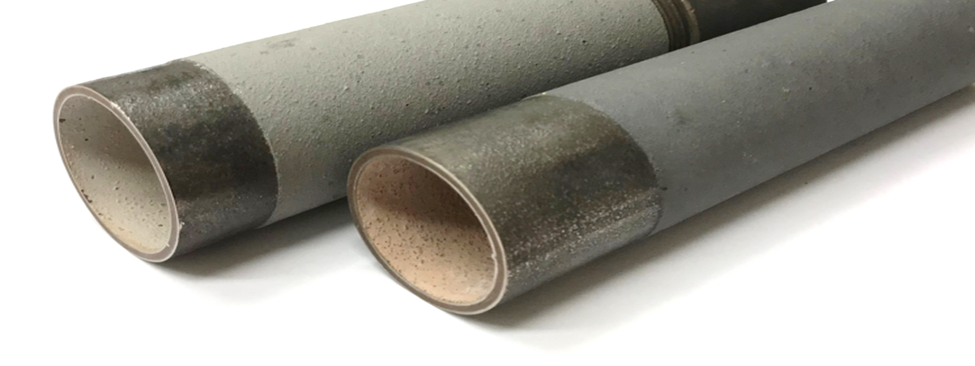

CA Lance pipe

Protecting Thermocouple against Heat Resistance

For the duration of smelting of Aluminum into liquid, the temperature will be around 960°C, hence in this time keeping a stable temperature is a required and therefore CA Lance can be used in this step to protect the Thermocouple and then put into the Smelter for measurement. CA Lance pipe is generally produced with a one-sided welded closed end to protect Thermocouple.

Structure of CA or Calorized Lance pipe:

- Refractory Coating: CA Lance has a thin refractory coating on the inner surface that protects the steel from direct contact with the oxygen flow. On the outer surface, it has a thick refractory coating that effectively protects the steel from any kind of heat attack.

- Calorized Layer: This Lance has a homogeneous calorized layer both inside and out of the lance.

- Micro view of Calorized Layer: The calorization process is the process when aluminum diffuses into mild steel, and it is then heated up to 1,000°C forming a heat-resistant aluminum-iron alloy (calorized layer) over the surface of mild steel.

Photo showing one-side welded close-end CA Lance pipe

Maintenance of Aluminum Plants

During Aluminum production process, molten aluminum sticks to the wall, and also on the floor. Thus, this finishing process requires workers to clean up the plant due to the situation. Therefore, it is required to use steel pipe with a powerful flame to burn and remove the molten aluminum.

Thermic Lance (TH)

Thermic Lance (TH) is a steel pipe filled with wires or a mixture of wires and an inner tube. The burning lance generates a powerful flame up to 4,000°C without any vibration and noise to break up materials quickly. This lance is mostly used for burning and cutting large iron castings, refractory materials, concrete, stainless steels, brass, non-ferrous metal, ceramic, natural stone, etc. with high-level of proficiency and productivity.

Conclusion:

To reduce the costs and boost the productivity, it is ideal for aluminum makers to use Calorized and Thermic Lances.

Therefore, to know more about our products, please feel free to contact us at sales@daiwaanayasteel.com.

- Specialized steel hardware – punched, pressed, galvanized, powder coated.

- Steel pipes and tubing – specialized, color coated, galvanized and structural.

- Our Lance pipes are produced by Daiwa Lance International in Vietnam.