Metallurgy is often associated with factories filled with blazing furnaces, where temperatures can reach thousands of degree Celsius. In these extreme conditions, refractory materials play a crucial role. Heavy Lance, designed with a super thick refractory coating, is built to withstand temperatures exceeding 2,000°C while offering excellent resistance to wear and chemical corrosion. This article will help us understand what makes Heavy Lance exceptionally heat and thermal shock resistant.

Super Thick Refractory Coating for Heavy Lance

Source: Daiwa Lance International

What is Heavy Lance?

Heavy Lance is a specialized lance pipe made from heat-resistant calorized steel and coated with an exceptionally thick refractory layer—15 to 30 times thicker than conventional coatings. This advanced coating significantly enhances its resistance to extreme heat and thermal shock.

Common applications of Heavy Lance include:

• Blowing oxygen into Electric Arc Furnaces (EAF), Ladle Furnaces (LF), or during the VOD process.

• Blowing argon into the VAD process for alloy and stainless-steel production.

• Any other high-temperature applications requiring superior heat and thermal shock resistance.

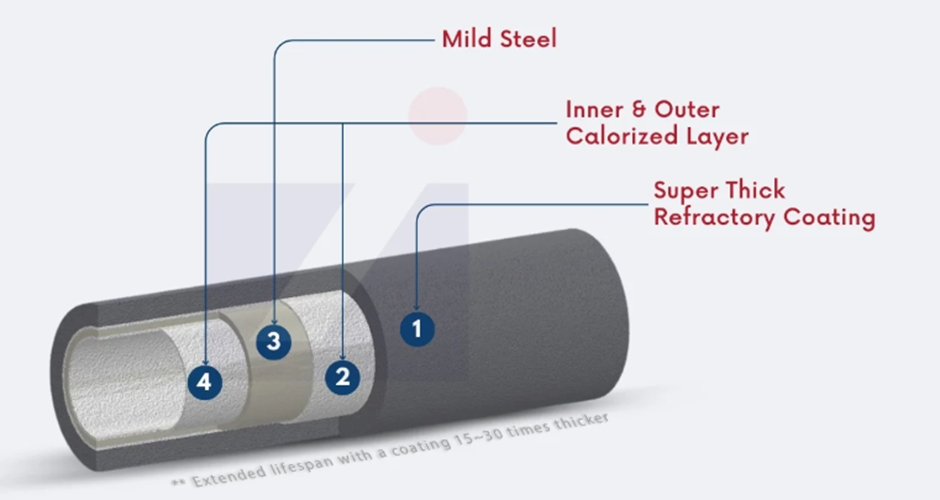

Structure of Heavy Lance

Heavy Lance is composed of:

1. A heat-resistant steel core (calorized lance) capable of withstanding temperatures above 2,000°C.

2. An outer layer of special thick refractory coating, made from materials such as aluminum oxide and silica, ensuring exceptional thermal shock resistance.

User Experience with Heavy Lance

Increased Durability and Strength

• Added Weight: The thick refractory coating adds some weight, but this trade-off results in greater durability and strength. The lance maintains its shape and resists deformation under extreme heat conditions.

• Superior Thermal Shock Resistance: Unlike conventional lances, which may bend or crack during argon blowing and liquid steel stirring, Heavy Lance retains its structural integrity even when exposed to rapid temperature changes.

Reduced Consumption and Cost Savings

• The thick refractory coating significantly extends the lifespan of the lance, reducing the need for frequent replacements.

• Operators can shift their focus from constant maintenance to more productive tasks such as process optimization.

Extended Lifespan

• The combination of high heat resistance and reduced wear translates into an extended service life.

• For precise data on its lifespan under various metallurgical conditions, samples can be tested to evaluate durability in specific environments.

Conclusion

The advanced refractory composition of Heavy Lance enhances its ability to withstand high temperatures, thermal shock, and deformation, making it an essential tool for furnace operations.

Using the right refractory materials for lancing can improve furnace efficiency, reduce pipe replacement time, and minimize operational issues such as cracking and breakage.

For more information, please contact our sales team at sales@daiwaanayasteel.com

Daiwa Anaya Steel Private Limited is a part of Anaya Steel, LLC (US parent company). Our company has over 30 years of involvement in steel products. It mostly deals in:

- Specialized steel hardware – punched, pressed, galvanized, powder coated.

- Steel pipes and tubing – specialized, color coated, galvanized and structural.

- Our Lance pipes are produced by Daiwa Lance International in Vietnam.