There are various types of Calorized Lance Pipes used for steel manufacturing process. Hence, it is challenging to understand which types would be suitable for customers’ furnace and customers’ desirable usages. When the customers consider buying Calorized Lance Pipes, it is legit for the customers to have a lot of queries relating to the technical specifications and hence expects us to provide them with sufficient knowledge. Customers want to feel reassured after they meticulously understand all the factors that affect the quality and practical application of Calorized Lance Pipes.

We would therefore like to introduce the most common measures when buying Calorized Lance Pipes, so that it will help the customers to know which factors to consider before deciding to purchase the same.

Technical Factors to consider when buying Calorized Lance Pipes

Source: Daiwa Lance International

Connection Type: Calorized Lance

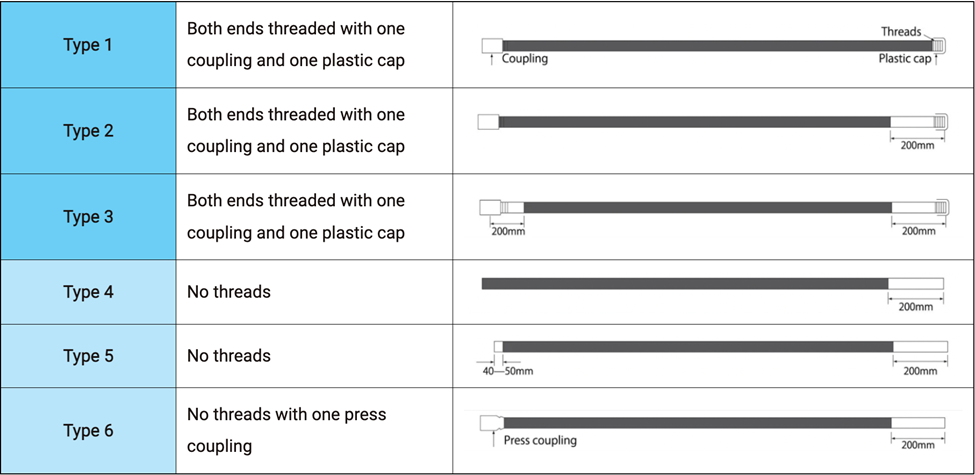

A Calorized Lance Pipe is one of the essential equipment for high temperature melting metal. With the same objective of the connection, each customer has their own desirable demands on several connection types. There are basically 6 types of connections with similar purpose depending on customers requirement and desirable practices.

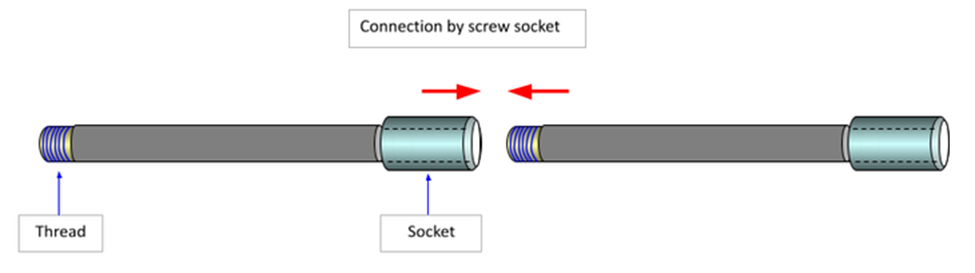

Calorizing Lance Pipes of Type 1, 2, 3 will include both ends threaded with one coupling at one end and the other end with one plastic cap. This way it helps to connect the pipes quickly and immediately while fully consuming the Calorized Lance Pipes.

With Calorized Lance Pipes of types 4 and 5, the pipes are designed and produced with threadless ends subject to customers’ desirable requirements. Here you can use a single pipe and connect the pipes by welding them together to prevent any air leakage.

For Type 6, we would require a Press machine to connect the pipes using a threadless coupling. With a higher volume for consumption, you can consider using this type thanks to the good air leakage resistance and easy operation.

Technical Specification

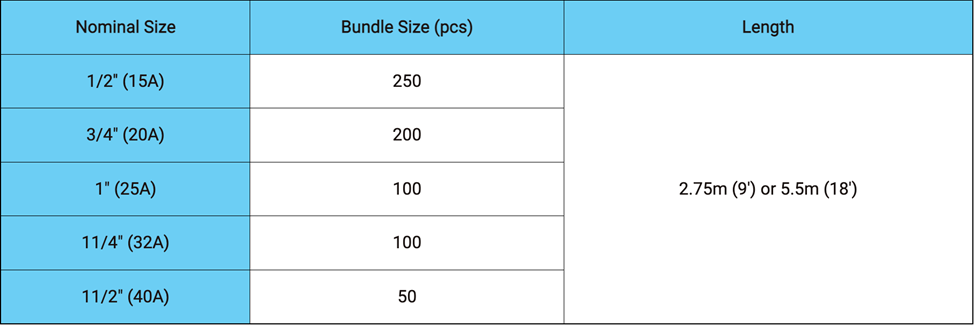

- Outer Diameter: Tubing is determined by the OUTSIDE DIAMETER (O.D.), measured in inches. We can supply the Calorized Lance pipes from 6 mm to 60 mm OD, and also we suggest that for

- Tapping purpose – OD 17.3 mm or smaller would be recommended.

- Oxygen injection – it depends on the size of furnace -generally the OD of Calorized Lance pipes are between 21.4 mm – 33.3 mm

- Carbon powder injection – it is recommended to use the Calorized Lance pipe with OD 42.0 mm or bigger.

- Length: The available standard length for Calorized Lance pipe production is between 2.75 m – 5.5 m. Now, depending on customer’s space of processing near the furnace and other additional requirement, the length of the lance would be produced.

- Thickness: The standard thickness of Calorized Lance pipe that can produced is between 1.5 mm – 3.9 mm.

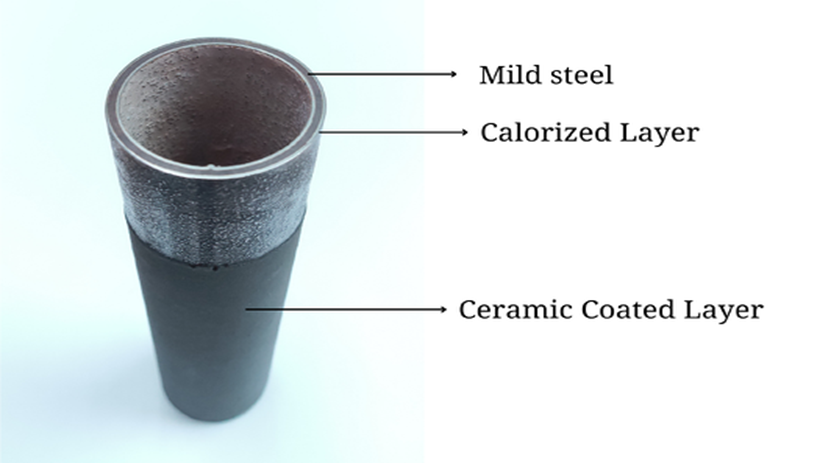

Thickness of Ceramic Coated Layer: The customers can be provided with single, double, or triple layers of ceramic coating depending on the requirement of the customer. The best option for Calorized Lance pipe is designed and recommended to use is with single Ceramic Coated layer. The customers who are concerned from electric shock during processing, generally requests for double and triple layered lance, however, in this case, price of lance would increase, but the weight would not be much heavier.

Delivery for Shipment: Considering the length of Calorized Lance pipe, 20′ or 40′ containers are deemed to stuff cargo and ship it to the customers. The stock of lance pipes in Europe and Japan are delivered by the cargo quickly by trucks. In most cases, it takes 3 ~ 4 weeks to prepare the cargo and organize shipping. The greater the quantity, the longer it takes to prepare the cargo.

Conclusion:

Calorized Lance Pipes turn up in a wide variety and are utilized as consumables throughout the steel manufacturing process. It is quite interesting to determine which varieties would be appropriate for customers’ furnaces and preferred uses. Customers, thinking about purchasing Calorized Lance Pipes generally has a lot of questions about the technical details but now we hope this above piece of information will be helpful to the customer.

To know more about CA lances, please feel free to contact our team to get more precise information at sales@daiwaanayasteel.com.

- Specialized steel hardware – punched, pressed, galvanized, powder coated.

- Steel pipes and tubing – specialized, color coated, galvanized and structural.

- Our Lance pipes are produced by Daiwa Lance International in Vietnam.