Generally, Thermic Lances are used extensively in the construction sites and steel mills due to its proven capacity and small sizes to cut large steel scrap materials.

However, powerful cutting is not the only feature of the product, it can also be utilized for several other purposes like in Blast Furnace steel mills.

Today, in this article we shall be exploring numerous circumstances where we can utilize this multi-purpose oxygen lance pipe.

Use of Thermic Lances in Blast Furnace of the Steel Mills

Source: Daiwa Lance International.

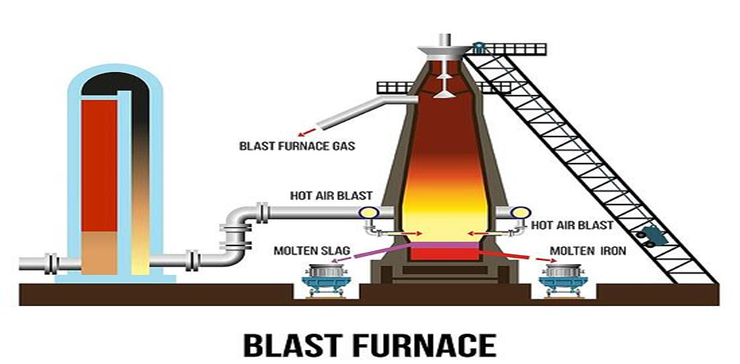

The Blast Furnace or BF is a form of metallurgical furnace that is used to produce iron from iron ore in the steel mills.

The mechanism of Blast Furnace is that it works by using a blend of natural resources including iron ore, limestone, or coke from top to bottom and using hot air pressure of about 1200˚C from both sides of the vertical shaft to heat the materials inside it into tiny pieces.

In the next phase of steelmaking, the chemical reaction and the hot air flow within the furnace will be made to transfer the molten iron and the molten slag to the manufacturing unit of steel factory.

As we can see from the above image, the operation of blast furnace is quite dangerous and time consuming for processing the materials for making steel.

Some of the difficulties include removing slags stuck in the mechanical equipment, opening the tap hole and cleaning slags on the ground, where the Thermic Lance comes to the rescue.

Uses of Thermic Lances

· Tap Hole Opening

Opening the tap hole is one of the most hazardous actions in Blast Furnace.

Exposure to extreme heat of Blast Furnace can lead to unexpected accidents and damages to workers.

Therefore, for safe and efficient opening of Tap Hole, the thermic lance with extended length, light weight, and heat resistant capacity of up to 4000˚C which is higher than the melting point of many metals comes to the rescue. This helps the workers to maintain safe distance and carry on with their work efficiently.

Slag Removal in Mechanical Equipment

The accumulation of solid slags that is stuck in the mechanical equipment like tundish nozzles or ladle cars after the iron making process can worsen the operating performance. In some cases, the equipment also gets damaged and then it becomes so costly for its repairing and maintenance that it ultimately gets to be replaced by a new one. This is what incurs huge cost which is not expected in the steel producing process.

To get rid of this situation, one can take the advance measures of melting the slag that is situated at the corner of the mechanical equipment through the Thermic Lances. In this case, one end of the Thermic Lance is heated at a temperature that is above the melting point of slag which is 1,780˚C and is then used in removing slag from mechanical equipment.

The main difference of Thermic Lance is that it requires a small flame to inflame the lance quickly. It requires lower effort and saves the times which ultimately helps in the steelmaking process at the Blast Furnaces in a great way

Cleaning Slags on the Floor

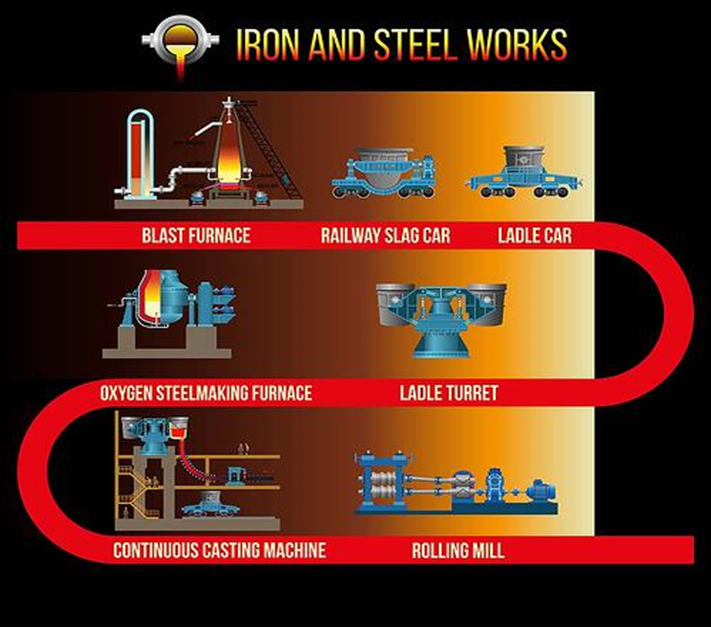

From the above image, we can see that after the scrap material manufacturing process for steel is completed in the blast Furnace, the molten slag is transported by the ladle car or railway slag car to ladle turret or oxygen steelmaking furnace or continuous casting machines which will then arrive at the rolling mills.

In this transporting process, the small portions of molten slags spills over the floor which in the form of hot liquid solidifies at the room temperature and becomes very difficult for the workers to remove or clean up the same. Here, Thermic Lances can help the worker to clean these stubborn slags by blowing oxygen through the Thermic lance and burning up the slags.

Conclusion:

To conclude, we must have got an idea about how Thermic Lances can help us in all the difficult areas of Blast Furnaces. The two main principles being fast ignition and combustion at high temperature enhances the efficiency and productivity of workers in the following above cases.

The Thermic lances can also be used by connecting two to three lances with the help of thread and socket which can enlarge the length of the pipe and ultimately helps the workers to use it by maintaining a distance and for reaching farthest areas without coming into direct contact. It completely depends upon the customers about how they want to utilize and apply the Thermic Lances.

Daiwa Anaya Steel is part of Anaya Steel, LLC (US parent company). Our group has over 30 years of experience in steel products mainly:

- Specialized steel hardware – punched, pressed, galvanized, powder coated.

- Steel pipes and tubing – specialized, color coated, galvanized and structural.

- Our Lance pipes are produced by Daiwa Lance International in Vietnam.