Aluminum Lance Pipes represent vital components across various industrial sectors, particularly within the realm of silicon metal production. This article endeavors to delve deeper into the specific applications of Aluminum Lance Pipes within this sector, shedding light on their pivotal role in optimizing critical processes and ensuring operational success.

Uses of Aluminium Lance Pipes in the Silicon Metal Sector

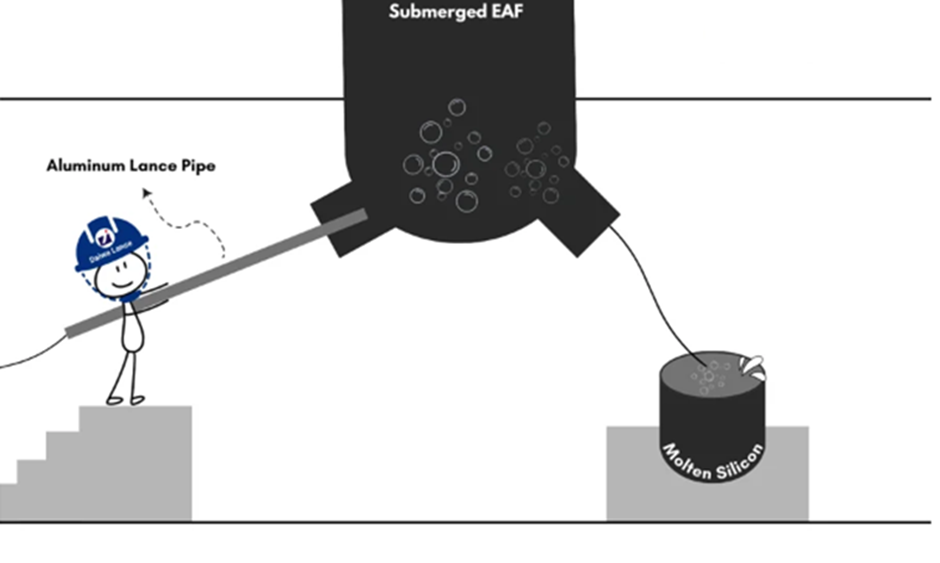

Source: Daiwa Lance International

Temperature Control:

Aluminum Lance Pipes serve as indispensable assets for the injection of oxygen into Submerged Electric Arc Furnaces (EAF) during silicon metal production. This injection process enables precise temperature regulation within the furnace, crucial for achieving optimal conditions conducive to silicon metal formation. Withstanding high temperatures, these pipes ensure meticulous control over oxygen injection rates, thereby facilitating efficient heat management.

Corrosion Resistance :

Silicon metal production environments are inherently aggressive, characterized by the presence of chemicals that pose a significant corrosion risk to equipment. Aluminum Lance Pipes mitigate this challenge through their innate corrosion-resistant properties, ensuring prolonged durability and minimizing maintenance-related disruptions. By resisting corrosion, these pipes contribute to enhanced operational reliability and cost-effectiveness.

Lightweight and Maneuverable Design:

The lightweight nature of Aluminum Lance Pipes enhances their maneuverability, a critical attribute within the dynamic operational landscape of silicon metal production. This feature facilitates ease of handling and precise positioning of the lance, optimizing process efficiency and enabling operators to navigate complex production environments with agility and precision.

Effective Thermal Management:

Silicon metal production processes entail high-temperature operations that demand meticulous thermal management. Aluminum Lance Pipes, renowned for their exceptional thermal conductivity, play a pivotal role in dissipating heat effectively. By efficiently transferring heat away from critical components, these pipes help prevent equipment overheating, thereby preserving operational integrity and ensuring consistent production performance.

Chemical Compatibility:

The inherent compatibility of aluminum with a wide array of chemicals used in silicon metal manufacturing underscores the versatility of Aluminum Lance Pipes. This compatibility ensures that the pipes remain inert to process gases, thereby safeguarding the purity and integrity of silicon metal materials throughout the production process. By maintaining chemical stability, Aluminum Lance Pipes contribute to the preservation of product quality and consistency.

Conclusion:

In summary, Aluminum Lance Pipes emerge as indispensable assets within the silicon metal production landscape, offering a myriad of benefits ranging from precise temperature control and corrosion resistance to lightweight maneuverability and effective thermal management. As the demand for silicon metal continues to rise in various high-tech applications, the importance of Aluminum Lance Pipes in enhancing production efficiency and ensuring operational reliability cannot be overstated. For those seeking to capitalize on these advantages and harness the expertise of industry-leading professionals, we invite you to engage with our team and explore the limitless possibilities offered by Aluminum Lance Pipes in shaping the future of silicon metal production.

To learn more about our Aluminum Lances, don’t hesitate to contact our sales team at sales@daiwaanayasteel.com.

Daiwa Anaya Steel Private Limited is a part of Anaya Steel, LLC (US parent company). Our company has over 30 years of involvement in steel products. It mostly deals in:

- Specialized steel hardware – punched, pressed, galvanized, powder coated.

- Steel pipes and tubing – specialized, color coated, galvanized and structural.

- Our Lance pipes are produced by Daiwa Lance International in Vietnam.