The most abundant element in the earth’s crust is oxygen, around 50%, followed by silicon (Si) at around 26%. The raw material for silicon metal production is SiO2 which is a compound of the above two most abundant elements and is detected all over the world. However, it requires a huge amount of electricity to produce silicon metal by reducing SiO2. Today, in this content, we are going to introduce our Aluminum Lance Pipe which will help our customers to know about our products and services and its involvement in Silicon Metal production.

Introduction: Aluminum Lances for Silicon Metal Manufacturing

Source: Daiwa Lance International

Introduction

Our Ceramic Coating Lance Pipe (CC) is generally used in the production of silicon metal. But iron (Fe) turns impure when it gets dissolved into silicon metal, hence our CC lance is not used with the highest effectiveness for production of high-purity silicon metal.

Therefore, the aluminum pipe is used for better purity of silicon metal. Although the melting point of aluminum is lower than that of iron, aluminum pipes alone cannot be served as lance pipes.

Thus, our plant has designed a specific type of Aluminum Lance to avoid the above-mentioned problems.

In this type, the Aluminum Lance is produced by an unique technology where a thick refractory ceramic coating is applied on the surface of the normal aluminum pipe to make it suitable for better silicon metal production.

Image of Aluminum Lance with Coating and without Coating

Silicon Metal Production

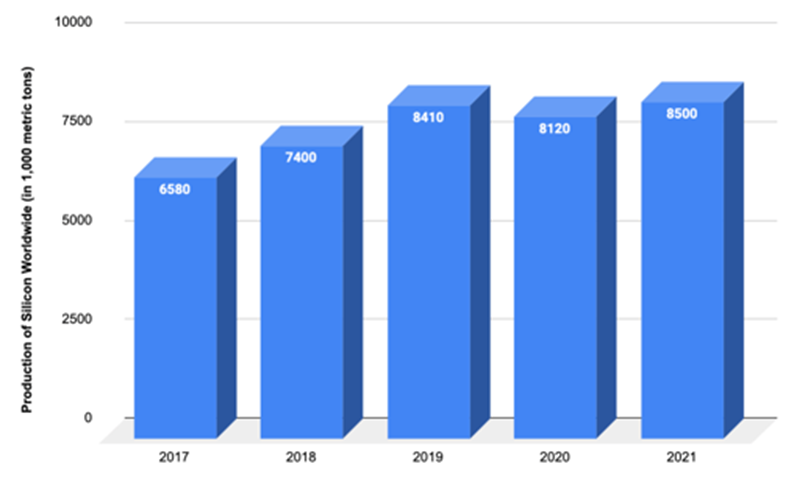

The surged demand for silicon is around 18% in 2021 and it is anticipated that it will rise more to around 9% this year. In many semiconductors markets the shortages are a consequence of the surge in demand. Solar power generated only around 2% of the world’s electricity in 2019, yet the installation of renewable energy sources is unparallelly high, and solar power has in general low production costs.

According to the International Energy Agency, by 2050, solar energy will be capable of supplying nearly enough of a third of global electricity consumption.

Chart of Worldwide Silicon Production

General Uses: Aluminum Lance

An aluminum lance pipe is used to create solar panels by processing silicon metal. The basic component used in solar panel production is silicon metal. Along with manufacturing oxygen lance pipes, we also manufacture aluminum lance pipes to aid in the fabrication of solar panels.

Image of the Silicon Metal and a part of the Production Plant

Presently we are supplying the below sizes of Aluminum Lance Pipe for Silicon Metal Production

- AL PIPE: OD 17.0 x 3.0mm x 3.0M

- AL PIPE: OD 17.0 x 3.0mm x 5.0M

- AL PIPE: OD 17.0 x 3.0mm x 5.5M

- AL PIPE with Ceramic coating: OD 17.0 x 3.0mm x 5.5M

- AL PIPE with ceramic coating: OD 21.0 x 4.0mm x 5.0M

Conclusion

We recommend our customers to use our specialized Aluminum Lance Pipe that increases productivity and helps in high purity of Silicon Metal manufacturing.

If you want to know more about our Aluminum Lance Pipes in order to maximize your performance requirement, please let us support you at sales@daiwaanayasteel.com.

Daiwa Anaya Steel Private Limited is a part of Anaya Steel, LLC (US parent company). Our company has over 30 years of involvement in steel products. It mostly deals in:

- Specialized steel hardware – punched, pressed, galvanized, powder coated.

- Steel pipes and tubing – specialized, color coated, galvanized and structural.

- Our Lance pipes are produced by Daiwa Lance International in Vietnam.