The customers from copper smelters are unaware of oxygen lance pipes, which are utilized for taphole drilling tools in the same. Hence, it is feasible to help these customers understand the practical use of oxygen lance pipes in copper refineries. By describing the processing technology of oxygen pipes, it is likely to convince them of the advantages of these lance pipes.

In this content, we shall try to explain the three main reasons why choosing our Oxygen Lance Pipes would be helpful for taphole drilling of copper smelters.

Reasons to Choose Oxygen Lance Pipes for Copper Smelters

Source: Daiwa Lance International

Copper Smelters

Copper smelters use several sulfide oxidizing procedures to extract elemental copper from copper concentrates. The smelting process melts the ore, mostly extracting the metal and decreasing or refining it. For separating the metal from the other components, the smelting process requires a huge amount of energy.

Image of copper smelter releasing hot metal during the production

A tap hole is a crucial component of a furnace and smelter. Since, hot metal and slag are continuously sealing the tap holes as a result of drilling and filling on a regular basis, one of the tap holes are remained open with two alternate tapings frequently overlapping for some time. Then the moment arrives to open the tap of the furnace which now becomes critical as the tap hole should be opened promptly and reliably whenever necessary with the help of oxygen lance pipes manually.

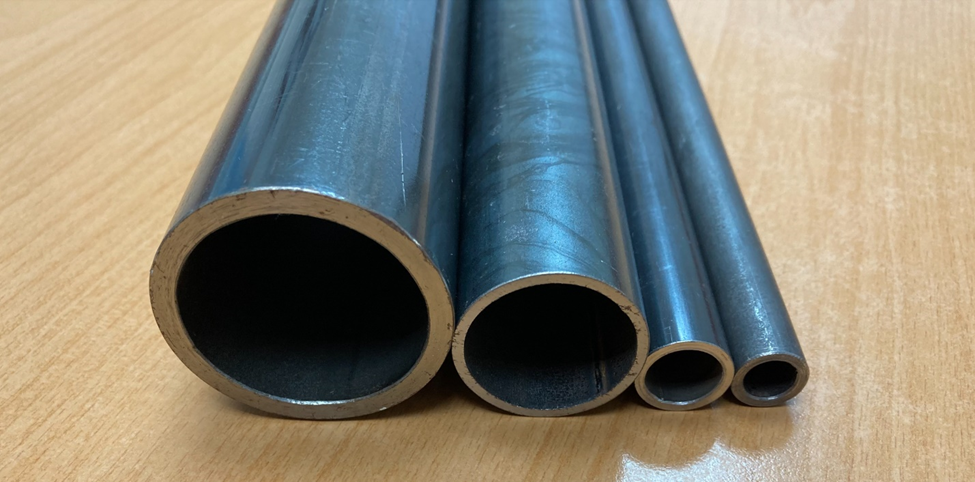

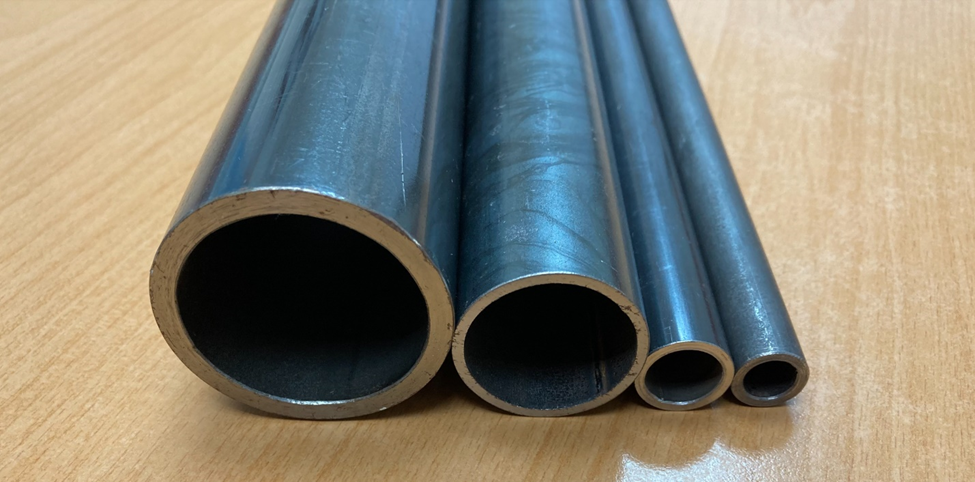

SC Lance Pipes

Our OEM produces several types of oxygen lance pipes and among them one of those is the SC Lance which can also be used for opening tap holes.

The word “SC” means “Self-Consuming”. SC lances are mainly used for removing stuck slag on converters, and cleaning tap holes on BF (Blast Furnace) and slag doors on EAF (Electric Arc Furnace). Firstly, the quality HRC is selected as a suitable material for lancing, then the SC lances are manufactured using high-frequency electric resistance welding equipment.

SC Lance Pipe of Size 13.8

SC Lance is a mild steel pipe that produces high temperature of over 3,000°C by burning itself and melts solidified steel and slag on equipment. The opening of tap holes is free of oil, grease, and other contaminants on the surface thus it leads to safety during the operating process. Our OEM can manufacture and supply small-diameter SC lance pipes also with high thicknesses.

Reasons to Choose Lance Pipes for Copper Smelters

SC Lance is a mild steel pipe that is recommended to use in Copper Smelter having various advantages:

- High Quality for Reliable and Consistent Use: SC Lance pipe is a high-quality mild steel pipe made from cautiously chosen raw materials, welded using high-frequency welding machines, and rechecked for welding leaks using electromagnetic inspection equipment, enabling us to provide reliable, high-quality mild steel pipes.

Image showing a part of high-frequency welding machine.

- Proper Processing: The products’ quality is monitored to maintain the usage performance under a severe production process that is from the beginning of checking of the materials for production to the final step of packing and delivering to the customers.

Images of precise packing and careful placing of the lances into the container

- High Safety: The SC Lance is carefully designed and connected with two pipes to minimize any sort of air leakage.

The pipes and their connection types:

Plain End: In this type of pipe, both the ends are plain

Threaded End: In this type, both ends of the pipes are threaded and fitted with a screw socket at one end and a plastic cap at the other end.

Swaged End: In this type, both the ends of the pipe are pressed down to reduce the diameter for use of straight coupling.

Pressed Coupling End: In this type, one end of the pipe is fitted with a pressed coupling, and the other end is plain.

Conclusion

Customers of copper smelters were somewhat unaware that oxygen lance pipes are also utilized as taphole drilling equipment. As a result, it is viable to assist consumers in understanding their practical use in copper refineries. By reviewing the processing technique of oxygen pipes, we may persuade the customers of the benefits of SC Lance pipes, specifically those are discussed in this content which are frequently used for taphole drilling.

If you wish to know more about our solution for taphole opening by oxygen lance pipes, please feel free to contact our dynamic team at sales@daiwaanyasteel.com

Daiwa Anaya Steel Private Limited is a part of Anaya Steel, LLC (US parent company). Our company has over 30 years of involvement in steel products. It mostly deals in:

- Specialized steel hardware – punched, pressed, galvanized, powder coated.

- Steel pipes and tubing – specialized, color coated, galvanized and structural.

- Our lance pipes are manufactured by Daiwa Lance International (DLI) in Vietnam.