Slag is a result of steel production which involves the procedure of extracting or refining metal from its ore.

Though the slag is considered to be waste or unusable rubbish but this waste leftover is a valuable material for construction sector especially in production of cement.

It is very tiresome for any production manager, steel worker or metal supervisor who are struggling day and night near the hot blast furnaces and electric arc furnaces removing the slags from torpedo cars, casting equipment and so on. Still, they have to work rigorously to remove the stubborn slags using different methods and techniques.

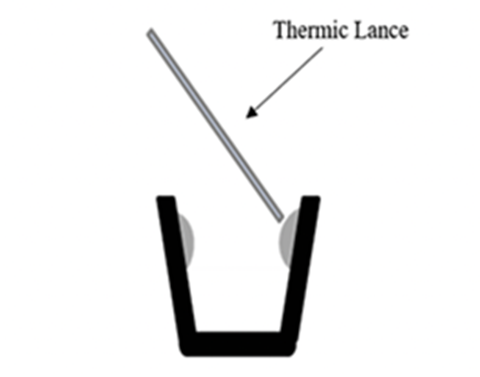

This is the reason, today we shall discuss about the different techniques of slag removal and how the Thermic Lance can ease this picture.

Different Slag Removal Techniques:

Source: Daiwa Lance International

Use of Drilling Mill for Grinding slag – As we know removing slag is very dangerous and also hard therefore to avoid any harmful impact a proper tool is required to remove these slags. One of such tools is a drilling mill. It is a specialized equipment which is used to grind steel slag and water slag into powder. The drilling mill is considered as an ideal equipment as it grinds the heavy steel slags which is further processed by drying, crushing, grinding. This equipment is mainly appropriate to grind heavy metals.

One of the drawbacks with this Grinding Mill is its high costing, installation time, complex machine instruction as well as skilled labors which causes hindrances when chosen this technique of slag removal.

Use of Hammer for Chipping slags – The other way of peeling off slag is by using chipping hammer. It is also considered as one of the conventional method due to its availability. The workers can even manually perform this slag removing using a hand-held chipping hammer. These are mainly used to remove less stubborn slags.

Although the application with chipping hammer is not that dangerous or difficult but it requires a great labor effort which brings question to the effectiveness and productivity of the work. The repetitive tasks reduce the efficiency in the entire automated steel making process.

Smelting slags with Thermic Lance – The melting point of slag is around 1780˚C which becomes difficult to remove from metals at a low melting temperature. This is the reason we need a material that can generate higher temperature and help in removing the slags. This is when the Thermic Lances comes to the rescue.

The Thermic lances can generate a heat of up to 4000˚C.

It can be used to remove stuck slags from:

- Casting equipment;

- Working floors;

- Ladle furnace;

- Mixer cars;

- Plant decks and many more.

The Thermic Lance Pipe by Daiwa is a steel pipe filled with inner tubes and wires which creates high temperatures and powerful flames. It burns itself producing high heat and by blowing oxygen. The steel wires inside the pipe promotes the combustion which ultimately helps in smelting the slags.

Working Principle of Daiwa’s Thermic Lance Pipes:

We shall explain the working principle of the Thermic Lance below so as have a clear view about how to use the same.

Daiwa made Thermic Lance is a steel pipe with a combination of steel wires and an inner tube inside the pipe. These wires inside the pipe helps in the powerful ignition of the flames when pressurized oxygen is blown inside the pipe. The high heat generated helps in burning the pipe itself which actually helps in smelting the stubborn stuck slags.

The chemical reaction of the Thermic Lance while combustion is:

Fe + O2 → Fe2O3 + Heat reaction (up to 4,000˚C)

We hope that the above information has helped you understand how the use of Thermic Lances helps in the slag removal very easily.

For more details about this product, please feel free to contact us at

Daiwa Anaya Steel is part of Anaya Steel, LLC (US parent company). Our group has over 30 years of experience in steel products mainly:

- Specialized steel hardware – punched, pressed, galvanized, powder coated.

- Steel pipes and tubing – specialized, color coated, galvanized and structural.

- Our Lance pipes are produced by Daiwa Lance International in Vietnam.