According to the World Steel Association’s Statistical Report, global demand for steel will increase by 2.2% in 2022. This signifies that the steel manufacturers must enhance their steel manufacturing process to get closer to the fast growth of steel demand all over the world. This has also increased the demand for scrap recycling in current years.

Although, large scrap recycling is one of the time consuming and cost ineffective step in the steel manufacturing process for taking into consideration.

This is why today we shall discuss about how Thermic Lance is effective for cutting Large Scrap Materials and help in daily steel production in the long run.

Thermic Lance – an optimum solution for cutting large scrap materials

Source: Daiwa Lance International.

Nowadays, many countries are considering that recycling scrap materials as a merchandise rather than a waste.

In the scrapyards, when the scraps are assembled at the terminal point, the scrap metal shredder machines are utilized by the operation workers to shred the large chunks of the scraps into pieces

Treatment Process – Large Scrap Materials in the Steel Mills

In the steel mills, before sending the scraps to the Electric Furnace (EF), a few steps are required to be followed to treat the scrap:

· Step 1: Sorting

· Step 2: Classifying

· Step 3: Cutting

· Step 4: Re-melting

Among the above four steps, the most important one is cutting where suitable machines and equipment are necessarily required.

This is where Thermic Lance Pipe comes to the rescue.

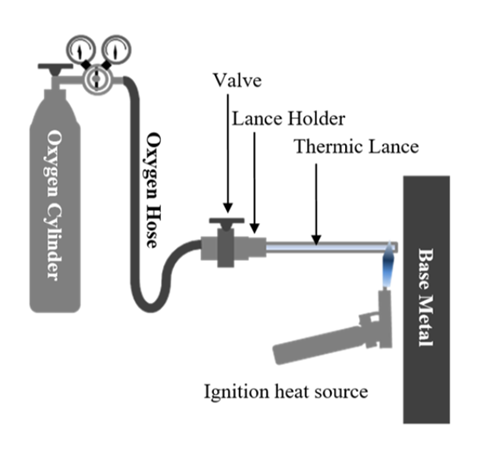

Oxygen Cutting Mechanism

This is the method of cutting and melting metal materials with oxygen which works on the principle that the tip of the steel pipes is heated and oxygen is blown into it. Now under high temperature the metal materials will burn aggressively generating a chemical reaction between iron and oxygen.

Thermic Lance is an example of this mechanism.

Why is Thermic Lance considered an optimum solution for cutting Large Scrap Materials?

- Easy Ignition: An acetylene torch is used to heat one end of Thermic Lance and then the oxygen is blown for cutting. By this method the flames ignite very fast and helps in cutting the large scrap materials like non-ferrous metals, iron casting, stainless steel, brass, ceramic, concrete, refractory materials or natural stones, etc

- Powerful and speedy metal cutting: When the pressurized oxygen is passed through the Thermic Lance having steel wires or combination of steel wires inside and an inner pipe, a powerful temperature of up to 4000˚C is produced without forming any noise and vibration to cut the large scrap materials quickly.

The reaction is:

Fe + O2 → Fe2O3 + Heat reaction

- Easy to use operation: This mechanism is very easy to operate as the below simple auxiliary devices can help the workers to blow oxygen into Thermic Lance to cut large scrap objects.

- Oxygen Cylinder

- Oxygen Hose

- Oxygen Regulator

- Air Valve

- Lance Holder

- Safety Tool

Various Standard and Custom-made dimensions: The standard and custom made outside diameter and weight offers several options for steel manufacturers to consider for a good performance of large scrap cutting in the Electric Furnace (EF) of the steel mills.

We hope the above piece of information will help our prospective customers to understand our products.

Daiwa Anaya Steel is part of Anaya Steel, LLC (US parent company). Our group has over 30 years of experience in steel products mainly:

- Specialized steel hardware – punched, pressed, galvanized, powder coated.

- Steel pipes and tubing – specialized, color coated, galvanized and structural.

- Our Lance pipes are produced by Daiwa Lance International in Vietnam.