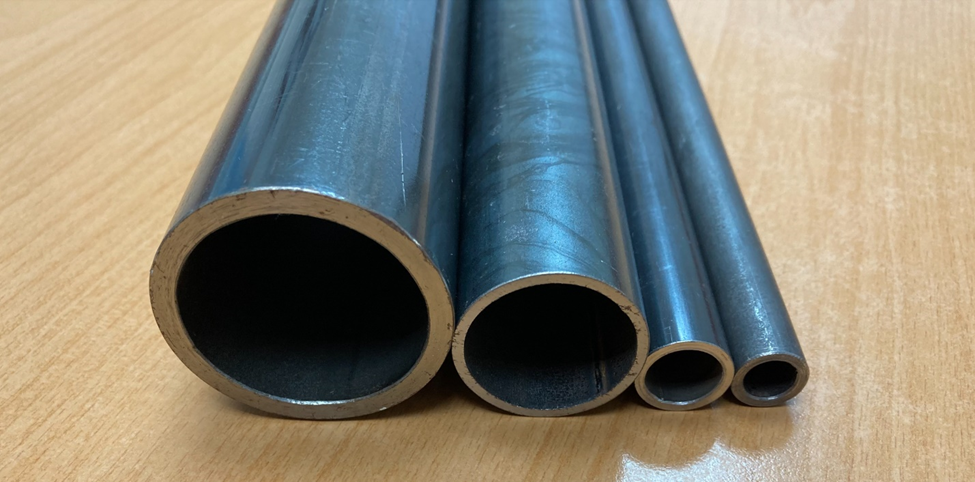

Silicon metal manufacturers have turned to Aluminum Lance Pipes as an alternative to oxygen lance pipes to reduce the unintended introduction of iron (Fe) into molten silicon (Si) during the purification process. Aluminum Lance Pipes serve the same purpose but without introducing iron content. This article delves into the structural elements and sizes of Aluminum Lance Pipes, addressing questions about their heat resistance and manufacturing quality.

CC Lance: Features and Cost-saving Benefits

End users look for efficiency enhancements through lance pipes for having diverse options, particularly for oxygen lancing. Understanding the economic and functional aspects of CC lances is crucial for selecting the right product for oxygenation needs. For applications not mandating high long-term heat resistance, the versatile CC Lance pipe is recommended.

There exist both similarities and differences among SC, CC, and CA lances. These differences arise due to their varying levels of heat and corrosion resistance. This blog dives into comparing the economics and characteristics of CC Lance with other lance pipe grades. This comparison will help our customers to identify the most suitable lance pipe for their specific applications.

The Complete Guide to our Lance Products

The world of steel pipes provides many opportunities to improve how they work for different purposes. One important way is oxygen lancing. This is when you use pipes to inject oxygen into a process. But choosing the right one to do this can be intricate. Since there are a lot of choices, it’s not always easy to figure out which one will help the most in the long run.

In this blog content, we want to help the customers understand all about these lancing pipes. We will try to explain everything in a simple way, so it can help our esteemed customers to make the best decisions for their needs.

Ceramic Coated Lance Pipe: Structure and Applications

Lance pipes are the additional alternatives for using steel pipes to enhance effectiveness depending on the uses and application for lancing activities. It becomes difficult for the customers to find the best lancing option that is suitable for a particular scenario so as to increase overall efficiency. This is the reason we try to explain our lancing products to our esteemed customers so that it helps them to find the appropriate product that will fit as per the requirement.

Therefore, today we shall be explaining about the CC Lances and its applications in various fields because of its corrosion resistance and moderate heat level characteristics.

Aluminum Lance: Application and Necessity for Silicon Metal Production

Silicon metal is an essential element in the production of various electronic devices and alloys. It is largely used in the manufacturing of semiconductors, aluminum alloys, and solar cells, etc.

The two most plentiful elements oxygen and silicon combine to form SiO2, which is found all over the world and is the preliminary ingredient for the formation of silicon metal.

The refining process is one of the essential steps in the production of silicon metal, which demands high-temperature conditions and non-ferrous materials for blowing gases. Hence, in this situation our Aluminum Lance Pipes comes to the rescue.

Today, in this content, we shall be going to discuss the application and usage of the Aluminum Lance Pipes.

Aluminum Lances for Silicon Metal Manufacturing

The most abundant element in the earth’s crust is oxygen, around 50%, followed by silicon (Si) at around 26%. The raw material for silicon metal production is SiO2 which is a compound of the above two most abundant elements and is detected all over the world. However, it requires a huge amount of electricity to produce silicon metal by reducing SiO2.

Today, in this content, we are going to introduce our Aluminum Lance Pipe which will help our customers to know about our products and services and its involvement in Silicon Metal production.

Calorized Lance Pipe and its Applications

The manufacturing process requires efficient cleaning equipment to remove spilled iron and aluminum metal from the furnace’s walls and floor. To cope with the flow of metal, it is essential to monitor the temperature of melted metals like zinc and aluminum. In this content we would like to introduce our main product, Calorized (CA) Lance pipe and discuss the quality benefits and applications of CA lance pipe.

Thermic Lance and its Applications

Thermic Lance (TL) is one of the high-performance products. Because of its varied uses, there are different needs and requirements for employing Thermic Lance. For effective use of the Thermic Lance, it is most favorable to comprehensively understand which type of Thermic Lance should be used precisely with its various applications.

In this content, we are trying to provide overall information with concrete examples of Thermic Lance applications.

Three Basic Types of Oxygen Lance Pipes for Electric Arc Furnace

Steel manufacturing by Electric Arc Furnace (EAF) is getting more accepted

day by day due to the decrease of 3/4 th amount of carbon emitted to the

environment. More and more steel makers are enhancing the production

performance and also treating the environment well. And subsequently,

there is a trend of shift from Blast Furnace to Electric Arc Furnace

extensively.

Each lance pipe that is used for the Electric Arc Furnace has several

purposes to improve the performance of steel making process. However,

there are some customers who still have concern about what kind of lance

pipe is suitable for the steel-making process in an Electric Arc Furnace, or

what type of lance pipe is applicable for ladle furnace cleaning and taphole

drilling. Thus, it is important that electric furnace steelmakers should

comprehend that there are appropriate lance pipes available for each

process.

Today, in this content, we are going to introduce the general processes in

which lance pipes are required at each process in EAF steelmaking, so that

customers can certainly improve the production by developing the

performance and cost saving.

Reasons to Choose Oxygen Lance Pipes for Copper Smelters

The customers from copper smelters are unaware of oxygen lance pipes,

which are utilized for taphole drilling tools in the same. Hence, it is feasible

to help these customers understand the practical use of oxygen lance

pipes in copper refineries. By describing the processing technology of

oxygen pipes, it is likely to convince them of the advantages of these lance

pipes.

In this content, we shall try to explain the three main reasons why choosing

our Oxygen Lance Pipes would be helpful for taphole drilling of copper

smelters.