Thermic Lance is one of the useful performance products. The demands and requirements to using Thermic Lance varies depending on different purposes. Also, there are cases where typical thermic lances with steel wires do not provide enough power of fire for combustion. At times, it takes large quantities of pipe for cutting large scraps. After a long time of usage of Thermic Lance, it becomes difficult for the operators to hold it therefore a newly introduced thermic lances with aluminum wires makes it lighter in weight and easy to handle. It is also optimal to use Thermic Lance with aluminum wires as the cutting operation can be performed very efficiently.

Thus, in this segment, we’d like to introduce our new Thermic Lance with aluminum wires and also the test result to ensure good performance quality of the same.

Technical Factors to consider when buying Calorized Lance Pipes

There are various types of Calorized Lance Pipes used for steel manufacturing process. Hence, it is challenging to understand which types would be suitable for customers’ furnace and customers’ desirable usages. When the customers consider buying Calorized Lance Pipes, it is legit for the customers to have a lot of queries relating to the technical specifications and hence expects us to provide them with sufficient knowledge. Customers want to feel reassured after they meticulously understand all the factors that affect the quality and practical application of Calorized Lance Pipes.

We would therefore like to introduce the most common measures when buying Calorized Lance Pipes, so that it will help the customers to know which factors to consider before deciding to purchase the same.

Various types of Lance Pipes and their usage in Blast Furnace and Electric Furnace

Every steel making processes uses different kinds of lance pipes. The Lance pipes primarily used in Blast Furnace (BF) and Electric Furnace (EF) are of various kinds as well. Hence, the customers must consider which lance type would be suitable for their specified stage in the steel production for better and effective performance.

In most cases, the customers are unaware about which particular lance would be required for a specific process in steel making. Thus, today we shall discuss about the variation of the lance pipes and their usage in each stage of the steel making process. This will help the customer manage the purchase plan considering the most suitable lance in accordance with their demands.

Thermic Lance and its various connection types

Thermic Lance is used in diverse industries and is applied for different purposes, including heavy scrap cutting, or melting to eliminate slags. However, the application of the Thermic Lance pipes for different purposes and their usage significantly affects the highest efficiency of the lances. Depending on each usage purpose, customer considers which type of connection of the Thermic Lance is suitable for them during the operation.

We have several customers with specific demands and depending on the same, the connection type is modified. Therefore, today we shall be discussing about all the available connections for connecting the Thermic Lance pipes depending on the operation application of the customers.

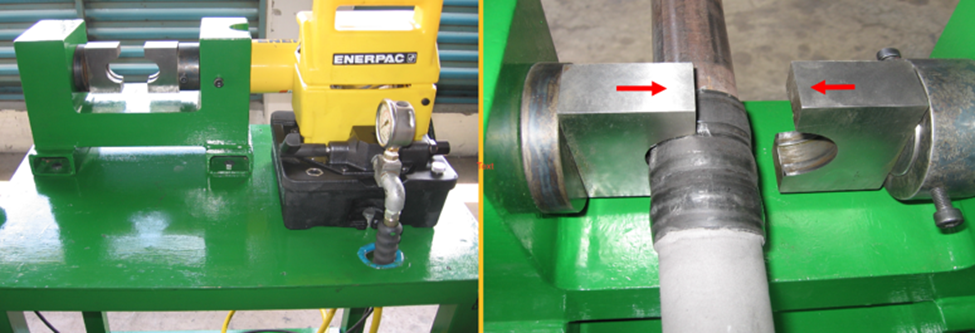

Lance Holder for Thermic Lance

Mostly the consumers use our lances mainly for the quality of the product as well as the easier usage and saving of costs.

Now, the consumers might have questions like how to connect the lances effectively so that one can use it without any hassle. Therefore, today we are going to discuss about an item which is engineered and designed to eliminate this question so that the consumers can use the lances conveniently. The item is named as Lance Holder.

Connecting Methods of Calorized Lance Pipes

Difference between MS pipe, Ceramic Coated Lance pipe & Calorized Lance Pipe

In this piece of information, we shall discuss about our different lances and their comparison with one another. It is evident that the end users of lance pipes have other options for using the steel pipes to improve the proficiency considering the applications for the lance pipes.

This is why, today, we shall be discussing about the three types of lancing pipes that are used in the refining and steel melting industries namely, Mild Steel Pipes, Ceramic Coated Lance Pipes and Calorized Lance Pipes and how they are different from each other.

Use of Renewable Energy in Steel Manufacturing

We already know that steel is manufactured from liquid iron from Blast Furnace. The heat from the BF’s stove area melts the metal by transforming pushed air into hot air. Whereas steel is manufactured from scrap in an Electric Arc Furnace. In general, EAFs generate heat using two separate types of Electrical Currents. These are the primary knowledge of the steel manufacturing process.

But today we shall be discussing about an important topic which is quite a point in the Steel World. It is the use of Renewable Energy in Steel manufacturing.

Safety and Effectiveness of Thermic Lance

Thermal Lances are used by many customers throughout the world. Many of them contemplates the safety and success of using Thermic Lance. It is usually used in steel mills, or construction sites as its small size and proven capability to cut solid and large pieces of steel scraps by generating a high temperature of up to 3,000oC ~ 4,000oC.

Therefore, today we are going to discuss about the steps to be followed for using Thermic Lances safely and effectively.

Benefits of Thermic Lances in EAF

Decarbonization is improving the environment in a positive way by transforming the global economy. Previously, the steel production was generally carried out in the Blast Furnaces but now Electric Arc Furnace (EAF) can be used in a different and more environment friendly way by using a metallurgical furnace which uses steel scraps as raw materials for generating steel rather than iron ores.

Therefore, today we shall be going to discuss about the benefits of Thermic Lance in EAF. Here, we will also see how EAF works to maximize operational systems and understand which type of Thermic Lance is applied for which situation.