The metallurgy industry is continuously evolving, with an increasing focus on cost reduction and efficiency enhancement. High-performance oxygen lance pipes play a crucial role in optimizing the metal-making process, and SC Lance stands out as a reliable solution. If traditional black pipes or mild steel pipes seem sufficient for your operations, you may wonder what sets our SC Lance apart. Below are four key advantages that demonstrate why our SC Lance is a superior choice.

The Essential Accessories for Oxygen Lance Pipes

Even after purchasing a premium-quality oxygen lance pipe, we may face challenges in achieving efficient blowing, heating, or cutting performance. What can bridge the gap between expectations and reality? The key lies in the often-overlooked accessories that are essential for oxygen lance pipe operations.

In this article, we delve into four indispensable accessories—lance holders, sockets, couplings, and press die sets—that play a vital role in enhancing the performance and safety of oxygen lance pipes. By understanding their functions and characteristics, you can optimize your operational efficiency while maintaining safety standards.

Uncovering the Distinctions and Similarities Between SC Lance and Mild Steel Pipe

In the realm of industrial manufacturing and construction, selecting the right type of steel pipe is crucial for efficiency and safety. This article delves into the distinctions and similarities between two prominent types of steel pipes: the SC Lance and Mild Steel Pipe. By exploring their definitions, purposes, compositions, coatings, and design constructions, we aim to provide a comprehensive understanding that will guide you in making informed decisions tailored to your specific applications.

Characteristics of the Thermic Lance (Thermal Lance, Burning Bar)

Thermic Lances are versatile tools recognized for their capacity to generate exceptionally high temperatures through a chemical reaction involving iron (Fe) and oxygen (O2), resulting in the formation of iron oxide (Fe2O3) and the release of intense heat. These remarkable devices, also known as thermal lance burning bars, play a vital role in numerous industrial applications.

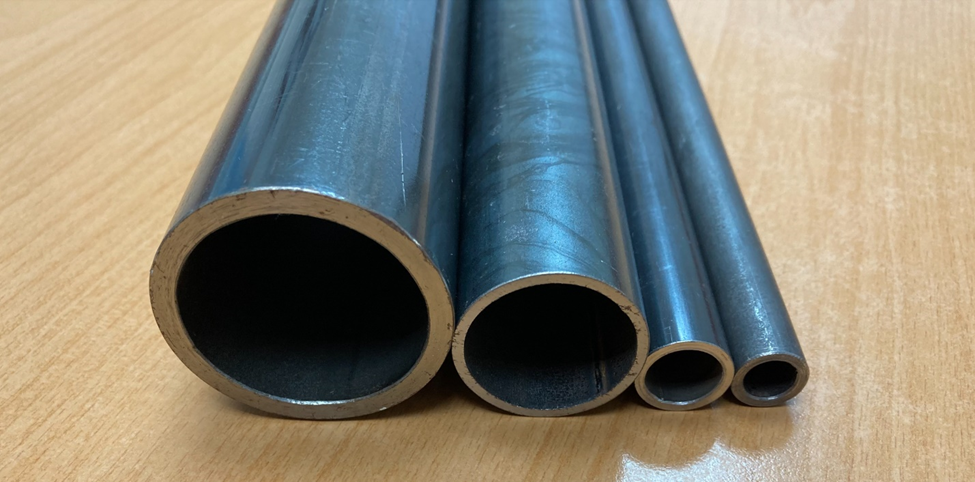

A Thermic Lance (TL) typically consists of a hollow steel pipe filled with steel wires and is primarily employed for tasks such as heating, melting, and cutting of large or heavy metal materials. Its functions encompass fusing metals, cutting through metal scraps, and cleaning industrial furnaces. The key innovation lies in the utilization of high-temperature oxidation heat generated by introducing pressurized oxygen into an ignited steel tube, thereby employing thermal cutting to efficiently disperse heat and burn through materials.

Therefore, let’s explore the numerous characteristics and qualities of Thermic Lances.

Overview of SC Lance Pipe

CC Lance: Features and Cost-saving Benefits

End users look for efficiency enhancements through lance pipes for having diverse options, particularly for oxygen lancing. Understanding the economic and functional aspects of CC lances is crucial for selecting the right product for oxygenation needs. For applications not mandating high long-term heat resistance, the versatile CC Lance pipe is recommended.

There exist both similarities and differences among SC, CC, and CA lances. These differences arise due to their varying levels of heat and corrosion resistance. This blog dives into comparing the economics and characteristics of CC Lance with other lance pipe grades. This comparison will help our customers to identify the most suitable lance pipe for their specific applications.

The Complete Guide to our Lance Products

The world of steel pipes provides many opportunities to improve how they work for different purposes. One important way is oxygen lancing. This is when you use pipes to inject oxygen into a process. But choosing the right one to do this can be intricate. Since there are a lot of choices, it’s not always easy to figure out which one will help the most in the long run.

In this blog content, we want to help the customers understand all about these lancing pipes. We will try to explain everything in a simple way, so it can help our esteemed customers to make the best decisions for their needs.

Calorized Lance Pipe and its Applications

The manufacturing process requires efficient cleaning equipment to remove spilled iron and aluminum metal from the furnace’s walls and floor. To cope with the flow of metal, it is essential to monitor the temperature of melted metals like zinc and aluminum. In this content we would like to introduce our main product, Calorized (CA) Lance pipe and discuss the quality benefits and applications of CA lance pipe.

Use of SC Lance Pipe for Incinerators with The Blast Furnace Concept

Keeping clean environment is a necessity that many countries and organizations are trying to follow. Many countries tend to use incinerators for burning wastes, and after that toxic substances are dissolved into the land and sea, posing health hazard to the residents in the vicinity. Many users are aware of the negative environmental effect of burning waste by incinerators, but most are unaware of the existence of incinerators that utilize the modern technology to reduce CO2 emissions.

In fact, the users should understand the detail that they can also use oxygen lance pipes in incinerators that processes industrial wastes by using the blast furnace concept.

Therefore, today in this content, we’re going to introduce the operational system of an incinerator that treats waste using the blast furnace concept along with the application of SC Lance 21.7mm x 2.8 mm x 4000mm. We shall also direct that how is it possible to show the presence of incinerators that do not emit hazardous substances and also the effectiveness of oxygen lance pipes.

Reasons to Choose Oxygen Lance Pipes for Copper Smelters

The customers from copper smelters are unaware of oxygen lance pipes,

which are utilized for taphole drilling tools in the same. Hence, it is feasible

to help these customers understand the practical use of oxygen lance

pipes in copper refineries. By describing the processing technology of

oxygen pipes, it is likely to convince them of the advantages of these lance

pipes.

In this content, we shall try to explain the three main reasons why choosing

our Oxygen Lance Pipes would be helpful for taphole drilling of copper

smelters.