Keeping clean environment is a necessity that many countries and organizations are trying to follow. Many countries tend to use incinerators for burning wastes, and after that toxic substances are dissolved into the land and sea, posing health hazard to the residents in the vicinity. Many users are aware of the negative environmental effect of burning waste by incinerators, but most are unaware of the existence of incinerators that utilize the modern technology to reduce CO2 emissions.

In fact, the users should understand the detail that they can also use oxygen lance pipes in incinerators that processes industrial wastes by using the blast furnace concept.

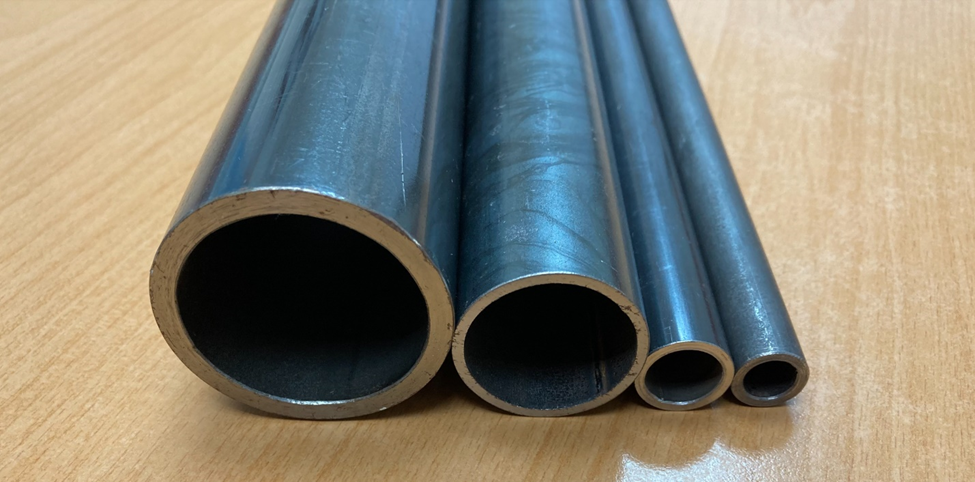

Therefore, today in this content, we’re going to introduce the operational system of an incinerator that treats waste using the blast furnace concept along with the application of SC Lance 21.7mm x 2.8 mm x 4000mm. We shall also direct that how is it possible to show the presence of incinerators that do not emit hazardous substances and also the effectiveness of oxygen lance pipes.