Thermic Lances are versatile tools recognized for their capacity to generate exceptionally high temperatures through a chemical reaction involving iron (Fe) and oxygen (O2), resulting in the formation of iron oxide (Fe2O3) and the release of intense heat. These remarkable devices, also known as thermal lance burning bars, play a vital role in numerous industrial applications.

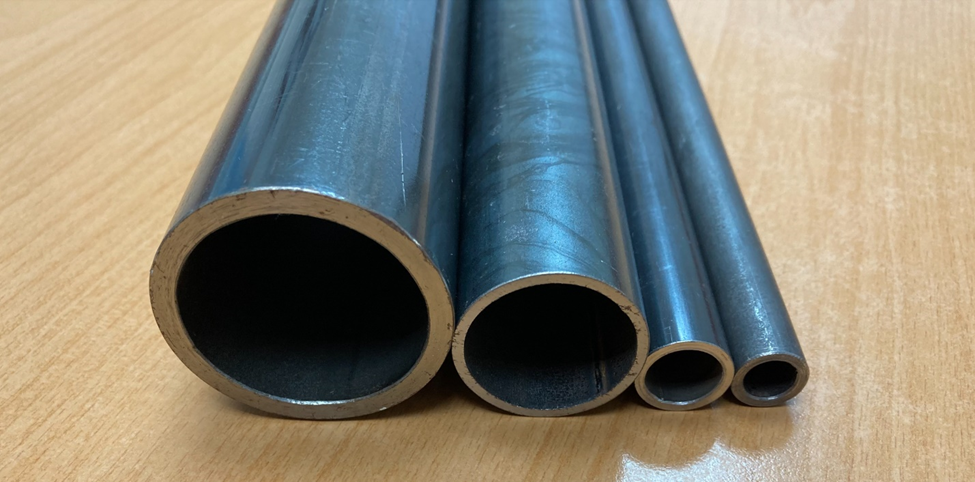

A Thermic Lance (TL) typically consists of a hollow steel pipe filled with steel wires and is primarily employed for tasks such as heating, melting, and cutting of large or heavy metal materials. Its functions encompass fusing metals, cutting through metal scraps, and cleaning industrial furnaces. The key innovation lies in the utilization of high-temperature oxidation heat generated by introducing pressurized oxygen into an ignited steel tube, thereby employing thermal cutting to efficiently disperse heat and burn through materials.

Therefore, let’s explore the numerous characteristics and qualities of Thermic Lances.